05 Innovative brackets for double-sided modules

5.1 Lateral structure system of brackets

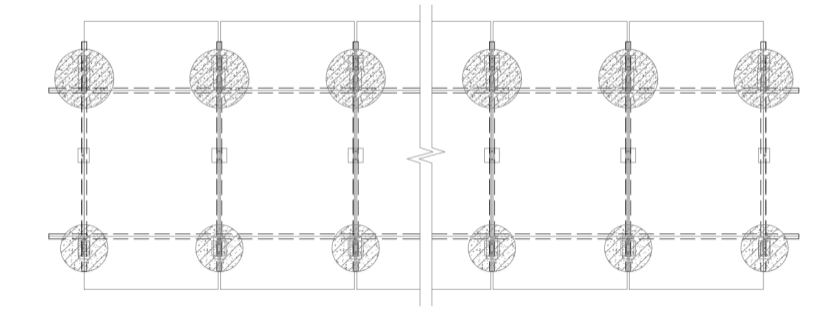

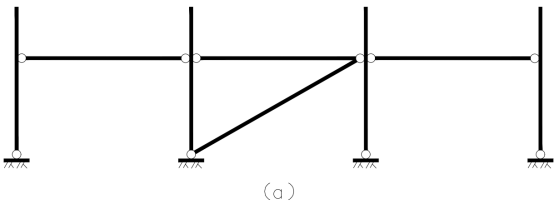

Since there should be no occlusion behind the double-sided photovoltaic module, the double-sided photovoltaic module is not suitable for the structural system of column "beam + purlin". Therefore, the purlins can be canceled and the photovoltaic modules can be directly connected to the beams on both sides, as shown in Figure 3.

Fig.3 Bracket plane of bifacial photovoltaic modules

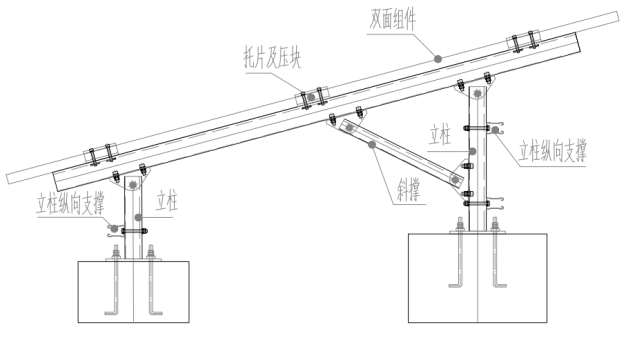

Beams are set on both sides of each photovoltaic module, and the modules are fixed to the beams by briquettes and pallets, and the beams are fixed to the foundation by front and rear columns. In order to ensure the lateral stability of the structure, one longitudinal support is provided along the longitudinal direction of the front column, and two longitudinal supports are set along the longitudinal direction of the rear column, and the façade of the double-sided photovoltaic module bracket is shown in Figure 4. The bracket structure system eliminates the longitudinal purlins, which effectively avoids its occlusion to the back of the module. At the same time, the longitudinal support set by the column provides the longitudinal stiffness of the bracket, so that the bracket forms a stable bracket system in the longitudinal direction. For specific installation effects, please refer to the application case in Section 7.

Fig.4 Façade of bifacial photovoltaic module brackets

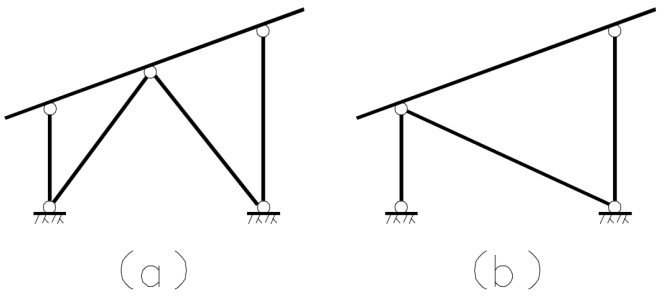

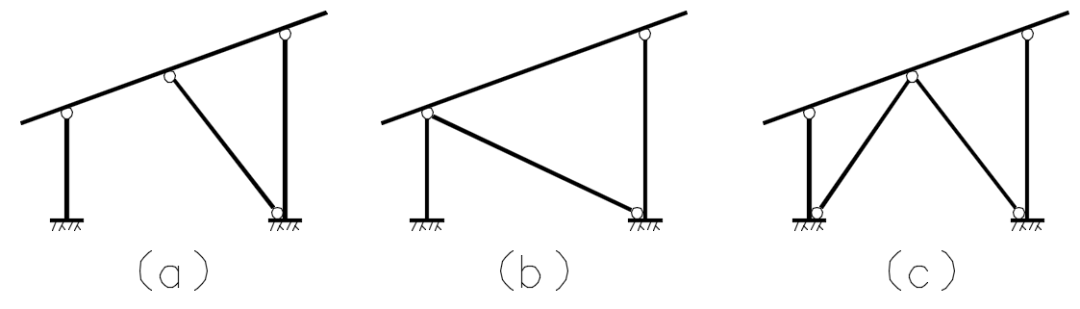

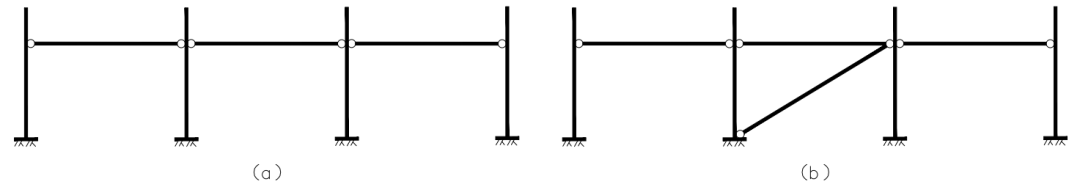

The transverse structure of the support shown in Figure 4 can be divided into two structural systems according to the different forms of connection between the column and the foundation, the form of column bottom hinge and column bottom consolidation. The hinge form of the column bottom is a row-type horizontal structure system, and the column bottom is consolidated into a row-type horizontal structure system. The two forms shown in Fig. 5 are row-frame transverse structure systems, in which the front and rear columns and foundations are hinged, and one or two transverse supports are used to provide lateral stiffness to form a stable structural unchanging system. The three forms shown in Fig. 6 are all rack-type transverse structure systems, in which the front and rear columns and foundations are consolidated, and one or two longitudinal supports are used to provide lateral stiffness and enhance the stability of the structure. The basic design is the same as that of traditional photovoltaic brackets.

Fig.5 Row-frame transverse structure system

Fig.6 Rack-type horizontal structure system

5.2 Longitudinal structure system of the bracket

The longitudinal structure system of the support is also divided into two structural systems according to the different forms of connection between the column and the foundation, the form of column bottom hinge and column bottom consolidation. The articulation form of the column bottom is a row-type longitudinal structure system, see Fig. 7. The column bottom is consolidated into a rack-type longitudinal structure system, see Fig. 8.

Fig.7 Longitudinal structure system of row-frame type

Fig.8 Rack-type longitudinal structure system

It can be seen from Fig. 7 that due to the articulation of the column bottom, the longitudinal diagonal brace must be set up in the vertical direction of the column to ensure that the longitudinal direction of the bracket forms a stable structural system. For the rack type longitudinal structure system, because the bottom of the column is fixed, the longitudinal support is determined according to the actual stress situation. Regardless of whether it is a row-type or a row-type bracket system, the longitudinal horizontal support is set on the column, and there is a certain distance from the back of the module, which can effectively avoid the obstruction of the double-sided photovoltaic module by the rods, so as to better give full play to the advantages of the double-sided module and increase the power generation.

5.3 Bracket material

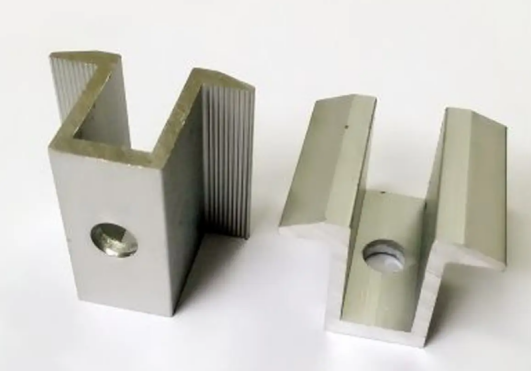

The advantage of this innovative bracket solution is that it can use conventional photovoltaic bracket members and materials, and has a wide range of applicability. The commonly used members are shown in Figure 9.

Fig.9 Commonly used members

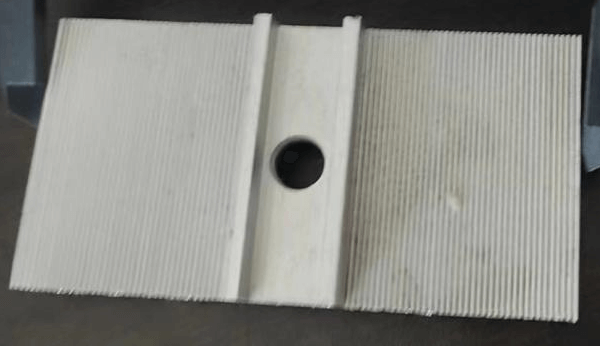

Fig.10 Briquetting and gasket

Figure 10 shows the commonly used briquettes and gaskets of photovoltaics, which are tightened with bolts and fixed with photovoltaic modules in the middle.