In today's rapid technological development, air conditioning is not only a simple device for regulating indoor temperature, it is differentiated into a variety of professional types according to different application scenarios, among which precision air conditioners and ordinary air conditioners are the most significant representatives. Although the two belong to the same air conditioning family, they are very different in terms of design concepts, application scenarios, operating characteristics and cost-effectiveness. This article will delve into the four core differences between precision air conditioners and ordinary air conditioners, revealing why precision air conditioners have become indispensable "constant temperature and humidity guardians" in high-precision fields such as computer rooms and laboratories.

1. Differences between application scenarios and service objects

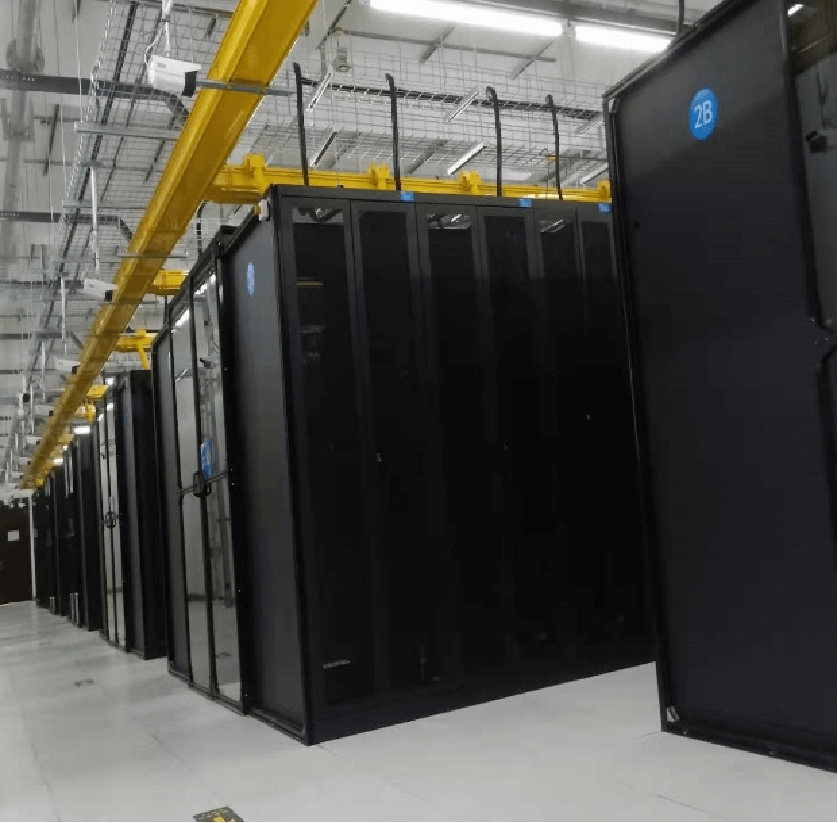

Precision air conditioning, as the name suggests, is specially designed for high-precision environments, such as computer rooms, laboratories, large medical equipment rooms, and outdoor communication base stations. It serves IT equipment, power distribution systems, and power supply equipment that maintain the continuous operation of these critical facilities, and requires the ultimate control capability of "constant temperature and humidity". Ordinary air conditioners, on the other hand, focus more on providing people with a comfortable working and living environment, and are commonly found in daily spaces such as living rooms, bedrooms, and offices. This difference directly determines the different emphasis on functional design between the two.

2. The distinction between conceptual principles and technical characteristics

The core of precision air conditioning, also known as process air conditioning, is to achieve precise control of temperature and humidity through high-precision control systems to ensure that environmental parameters are stable within a very small fluctuation range. It has a dedicated humidification system, a high-efficiency dehumidification system and an electric heating compensation system, which can be fine-tuned according to the data fed by the sensor to achieve temperature difference control of 0.1 degrees Celsius or even less. In contrast, ordinary air conditioners, as representatives of comfort air conditioners, pay more attention to the design of low noise, low air supply and low air speed to meet people's comfort requirements for the indoor environment.

3. Consideration of operating time and reliability

Precision air conditioners have shown great reliability in terms of operating time, and most data centers require 24-hour operation around the clock. This feature requires that precision air conditioners must be designed to operate continuously at high loads all year round and maintain extremely high reliability. Even in winter, when the external ambient temperature is extremely low, the precision air conditioner can be cooled normally through a controllable outdoor condenser, ensuring a stable environment in the computer room. Ordinary air conditioners, on the other hand, are mostly used in intermittent usage scenarios, and their design is not optimized for long-term continuous operation, so they may face operational difficulties in extreme environments.

4. Trade-off between operating costs and return on investment

Although precision air conditioners are usually higher than ordinary air conditioners in terms of initial investment, their operating costs are relatively low in the long run. The annual operating cost of ordinary air conditioners is often higher than that of precision air conditioners, mainly due to the advantages of precision air conditioners in terms of energy efficiency, intelligent control and component redundancy. For large-scale engineering projects, the use of precision air conditioning can not only significantly improve the operational reliability of equipment, but also significantly reduce operation and maintenance costs in the later stage, achieving a higher return on investment.

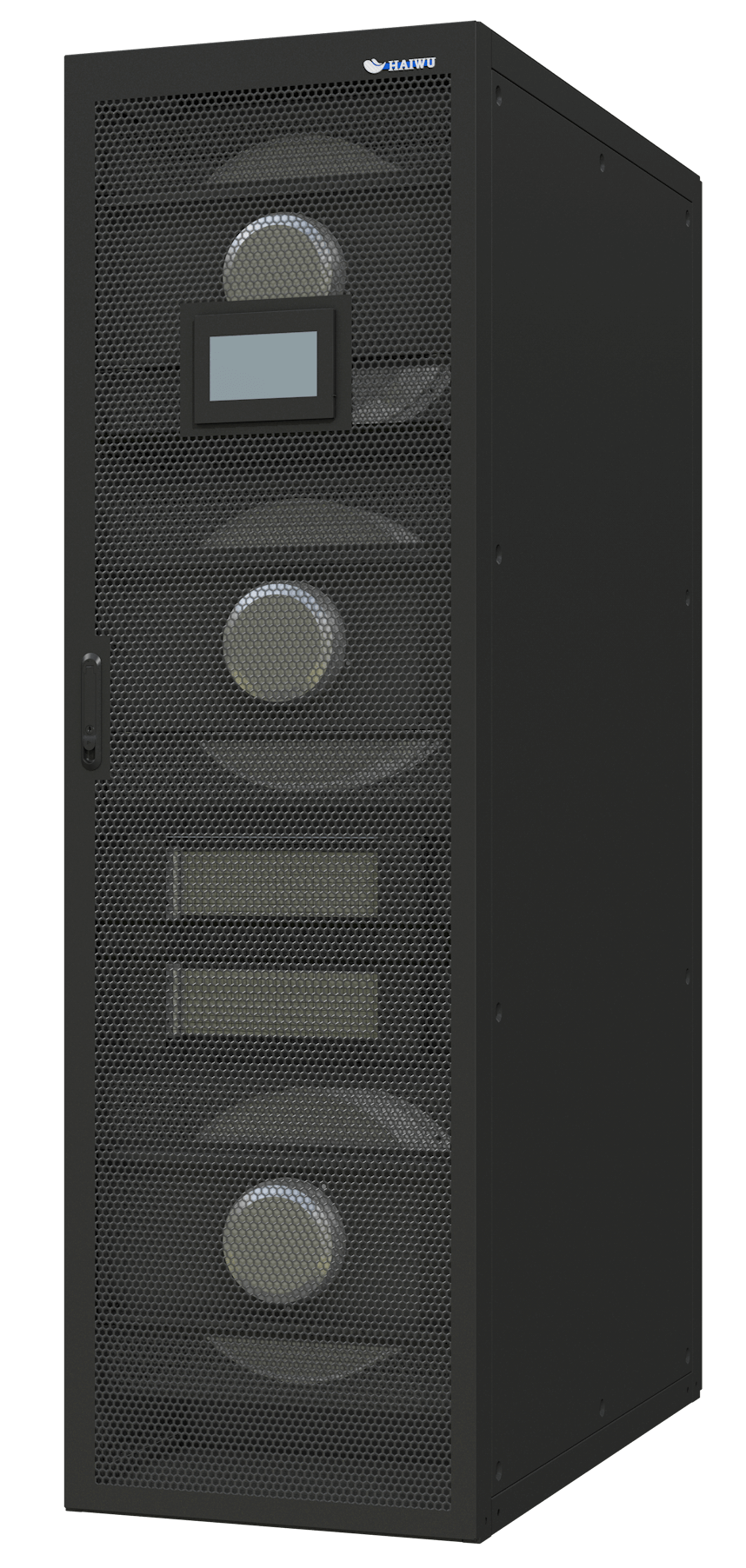

Haiwu inter-level fluorine pump machine room precision air conditioner: technology leading, high efficiency and energy saving

Among the many precision air conditioning brands, the precision air conditioner in the interstage fluorine pump machine room stands out for its excellent performance and advanced technology. The product adopts a full EC frequency conversion design, which automatically adjusts the cooling capacity and air volume output; The power-free wet film humidification module realizes humidification and energy saving; High return air temperature design improves energy efficiency; "full cabinet type one-line or U-shaped" evaporator reduces wind resistance; The series design of the pump cabinet system is highly integrated, and the energy saving effect is remarkable. In addition, the integrated high-efficiency and energy-saving algorithm supports multiple operating modes such as group control, rotation patrol, and stacking, providing users with more flexible and intelligent solutions.

To sum up, precision air conditioners and ordinary air conditioners show significant differences in multiple dimensions. In the pursuit of efficient, stable and reliable precision environments, precision air conditioners are undoubtedly a wiser choice. The precision air conditioner in the inter-stage fluorine pump machine room of Haiwu Lie, with its excellent performance and advanced technology, is becoming the first choice of more and more users.