With the continuous improvement of national energy consumption requirements for data centers, the pursuit of lower PUE and WUE has become a common goal of current data centers. Driven by external policy guidance and the internal demand for consumption reduction and efficiency improvement in data centers, data center liquid cooling, as an advanced and efficient cooling solution that can support higher power density, is in a stage of rapid development. In the southern region of our country, liquid cooling will be one of the most effective means to achieve lower PUE. In addition, liquid cooling solutions are also suitable for retrofitting old data center projects and are highly applicable to infrastructure. Therefore, this paper briefly describes some ideas and characteristics of liquid chilled water system design in combination with engineering projects.

The case project is located on the first floor of the data center, the computer room is designed according to the national standard A-level, and the liquid-cooled computer room adopts a water sprinkler fire extinguishing system and is equipped with fire and smoke exhaust facilities. The liquid-cooled computer room is designed with an indoor dry bulb temperature of 24±2°C, a relative humidity of 30%~60%, and a dew point temperature of 5.5~15°C.

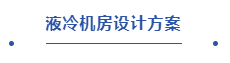

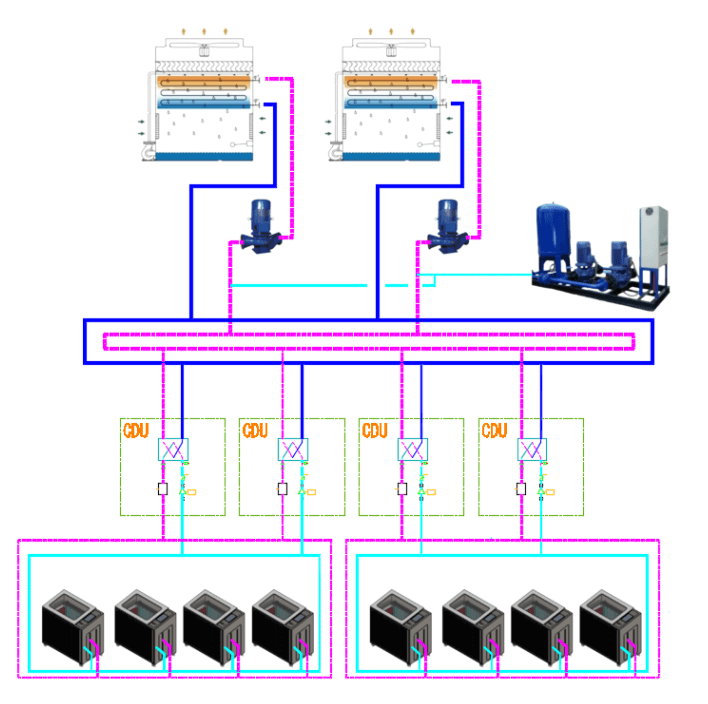

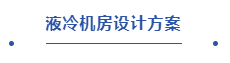

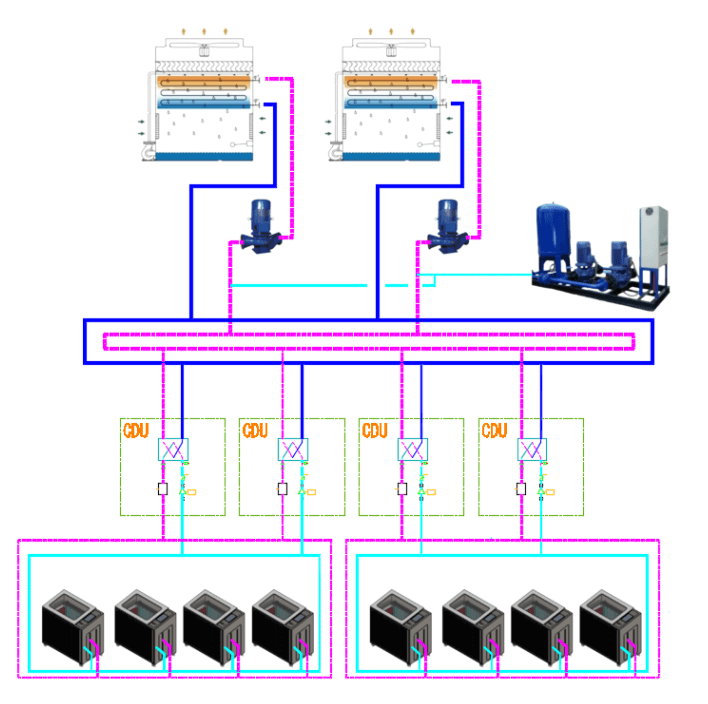

The heat generated by the liquid-cooled server is handled by the liquid-cooled system, and the room load and network cabinet are handled by the air-cooled room-level air conditioner of the liquid-cooled computer room. The liquid-cooled machine room adopts a 500mm high overhead floor. The immersion liquid-cooled computer room is equipped with a total of 8 liquid cooling modules, the IT capacity of a single liquid cooling module is 40kW, and a total of 4 CDUs (2 main and 2 standby) are set up in 8 liquid cooling modules, and the cold source adopts a closed cooling tower, and the redundancy is set according to 1+1. The outdoor primary cooling tower supply and return water temperature is 32/38°C, the indoor secondary side refrigerant supply temperature is 35/42°C, the primary side refrigerant is 30% glycol solution by volume, and the secondary side refrigerant is Naoh3000 solution. The CDU capacity is designed according to 170kW, and the CDU has a built-in plate change and secondary circulation pump. The closed cooling tower used for the cold source meets the needs of 100% natural cooling in the local extreme temperature. The cooling tower capacity is designed according to a single 340kW, the cooling water pump corresponds to the cooling tower one by one, and the outdoor pipeline is equipped with electric heat tracing. The liquid-cooled machine room is equipped with a constant humidity machine to ensure indoor humidity requirements.

01 Schematic diagram of liquid-cooled air conditioning system

02 System control logic

● Cooling tower control: Ensure the water supply temperature by adjusting the cooling tower fan speed, spray pump start and stop and bypass valve opening.

● Primary side pump: By adjusting the operating frequency of the primary side pump, the pressure difference between the most unfavorable end supply and return water is guaranteed.

● Equipment start and stop sequence: the cooling tower is corresponded to the water pump one by one, when the system starts, the water pump is turned on first, and then the corresponding cooling tower is started; When the system is turned off, the cooling tower is turned off first, and then the corresponding pump is turned off.

● Standby: two cooling towers are used and one is used as a backup, each other is spared, the two are always open, usually running at low speed, when one fails, the other is running at high speed to ensure the water supply temperature.

● The CDU unit includes secondary circulation pumps, valves, heat exchangers and other components, which are connected to the integrated monitoring system. By adjusting the opening of the electric control valve of the CDU inlet pipe, the temperature of the secondary side of the liquid supply is guaranteed; By adjusting the frequency of the secondary side water pump in the CDU to ensure the medium temperature of the liquid cooling module unit, the CDU unit controller directly collects the liquid level sensor and temperature sensor data to avoid single point failure. Pressure sensors are set up at the inlet and outlet of the pump to judge whether the pump is running normally, and pressure sensors are set up at the front and back of the filter to determine whether the sensor needs to be cleaned or replaced. The sensors involved in the control in the liquid cooling system are redundant.

This paper introduces the concept of the solution architecture of the liquid chilled water system in the data center in combination with the engineering project. This project can use natural cooling sources throughout the year, and directly use the closed cooling tower to exchange heat to meet the cooling needs of liquid-cooled servers without mechanical refrigeration intervention. For different projects, the temperature of the cooling medium should be checked according to the meteorological parameters of the project area. Whether it is cold plate liquid cooling or immersion liquid cooling, the cooling system (cooling tower cooling) principle is similar, and the two have different requirements for coolant medium, so they also have different requirements for pipe accessories and equipment materials.

Haiwu has mature practices and solutions in data center liquid cooling, and its consulting and design research institute has the first-class qualification of mechanical and electrical general contracting and the first-class qualification of architectural design, and has a professional design and construction team. At the same time, it is also equipped with BIM and CFD simulation teams to enable the continuous development of liquid chilled water systems in data centers. In the foreseeable future, liquid cooling systems, as an adaptable, efficient, and green cooling method, will gradually replace traditional cooling forms and lead a new era of data center cooling.