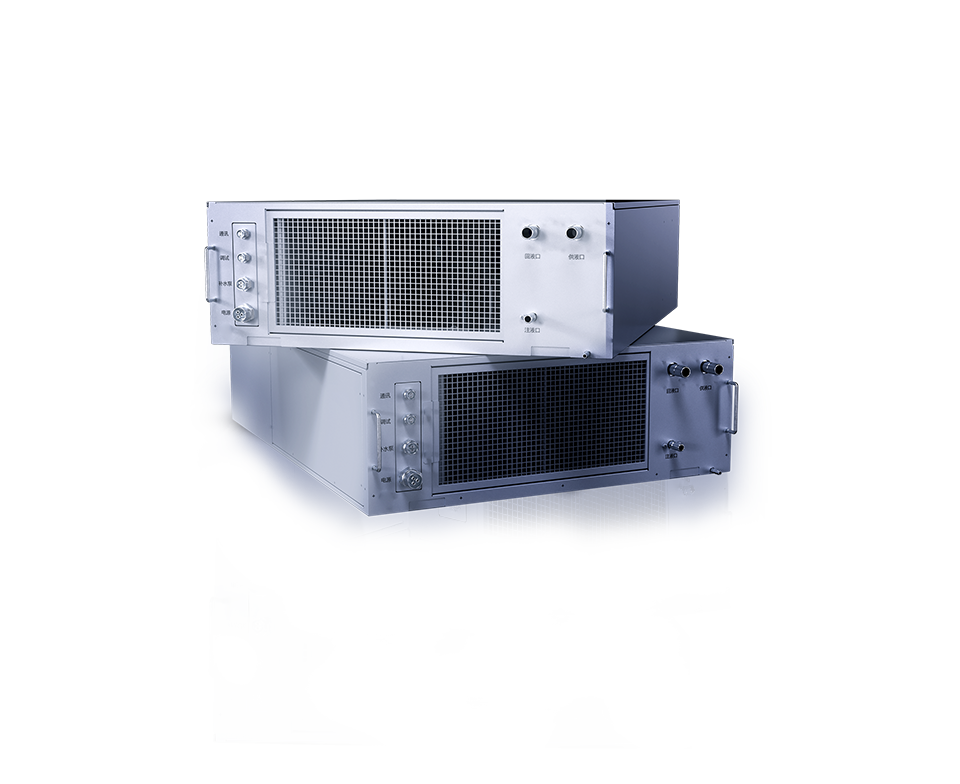

Dual-system design: In case of a single compressor failure, the unit can still provide 60% of the rated cooling capacity.

Intelligent and stable constant temperature function with an accuracy of ±1℃.

The liquid cooling pipeline system is prefabricated, featuring a highly integrated, self-sealing and leak-proof design.

The system adopts a full variable-frequency design, enabling the activation of a single system or a dual system based on demand, with stepless cooling capacity adjustment.

The dual-cooling-source design can achieve an energy savings of over 30% compared to ordinary variable-frequency air conditioners.

The system energy efficiency under rated conditions is as high as 3.0, significantly increasing the power-saving rate.

Intelligent centralized control technology makes centralized control more convenient and flexible, effectively preventing misoperations. The independently developed microcomputer intelligent control system is more suitable for accessing the BMS monitoring system. It has a real-time monitoring function for data collection and management, and can accurately analyze the operating status of the unit.