Two days ago, a data center operation and maintenance personnel of a financial system raised a question in the group: How many years does it take to replace a battery? Are there any special requirements in the financial industry?

The question seemed simple, but there was a heated discussion in the group.

The nosy editor found some information to help you sort it out:

Passerby A: The battery is guaranteed for 3 years, and it will be replaced after the warranty.

Passerby B: Mainly every six months the internal resistance test of the battery, and replace it in time if there is a problem.

Passerby C: Replace it in three years, but in many places, less than three years, the battery has problems, which is also related to the indoor environment.

So how often should the battery be replaced? How can maintenance improve battery life and maximize economic benefits?

Xiaobian checked the information hungry at night and learned that the battery is one of the most important components of the entire UPS system and the "last barrier" of the entire power supply system.

At present, the batteries configured in data center UPS are mainly valve-regulated sealed lead-acid batteries (VRLA), but with the development and improvement of battery technology, lithium batteries and fuel cells have gradually become one of the choices of users in the future.

Let's talk about batteries:

1. The selection and design of UPS batteries in data centers must fully consider the characteristics and development trends of modern data centers, and comply with the following principles:

(1) Excellent short-term constant power output characteristics

The excellent short-term (usually ≤ 30min) constant power output characteristics mean that the capacity of the battery can be reduced under the same load backup time requirements, thereby reducing the battery cost; Or use the same capacity battery configuration to increase the total backup time of the UPS system.

(2) High energy density

Selecting appropriate battery types and capacity, reasonably designed assembly structures, optimally utilizing the space in the computer room, improving the overall energy density of the battery pack, and helping to reduce the area and cost of the computer room.

(3) High stability

During the effective life of the battery, the failure rate should be low, and the repair or replacement caused by the failure or sudden failure of individual batteries should be avoided as much as possible, which is of great significance to the later safety and stability of the entire battery system.

(4) Fire and flame retardant

The plastic material of the UPS battery shell in the data center should meet the V0 flame retardant standard, and all exposed metal parts of the battery terminals, connectors and output bus terminals should be insulated and protected, and the battery rack should be grounded.

(5) Consistency

The consistency of the capacity, open circuit voltage, float charge voltage and other indicators of each unit of the data center UPS battery pack should comply with relevant standards.

(6) Earthquake resistance

The design of the UPS battery rack in the data center meets the requirements of resistance to level 8, and it is recommended to use soft connection for the connection between batteries.

(7) Easy to install and expand

The modular structure design of the battery and the provision of special installation tools can reduce the overall installation cost. The placement of the battery pack and the design of the battery pack frame should reserve the location requirements for later expansion.

(8) Easy to maintain and replace

The distance between the battery pack placement and maintenance channel should meet the requirements of daily maintenance and battery replacement.

(9) Long service life

Data center UPS batteries should have reasonable service life requirements, and too short service life will increase the instability and cost of UPS system.

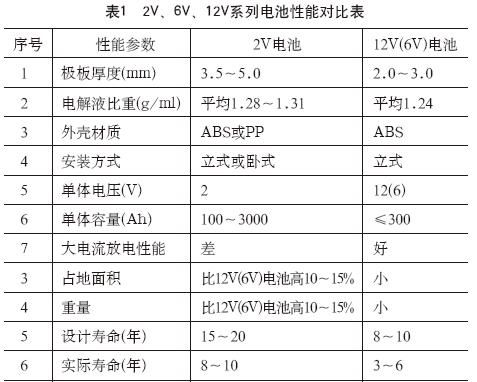

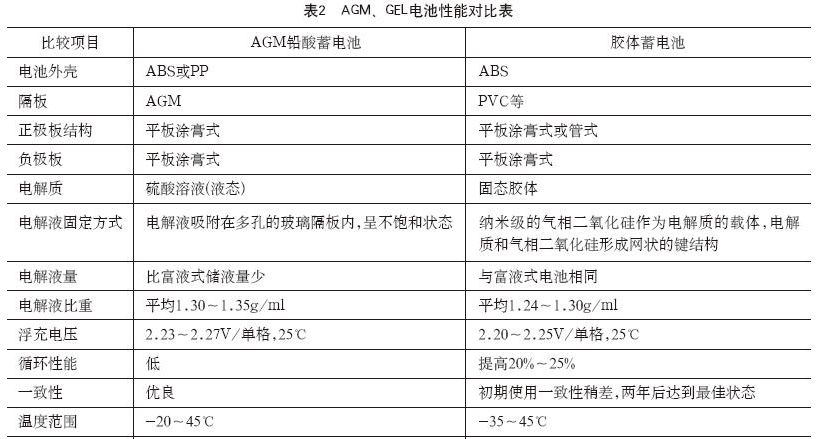

VRLA batteries for backup purposes are divided into 2V, 6V, 12V and other series according to the unit voltage level. According to the method of fixing the electrolyte, it can be divided into AGM (ultrafine glass fiber) battery and GEL (colloid) battery, and their comparison is shown in Table 1 and Table 2 respectively.

2. Key points of battery maintenance:

(1) Insulation pads should be arranged in the maintenance channel of the battery pack.

(2) Batteries of different manufacturers, different capacities and different models are strictly prohibited from being used in the same system.

(3) Valve-regulated sealed lead-acid batteries do not need to be charged for the first time before use, but should be recharged. The supplementary charging voltage should be carried out in accordance with the product technical specification.

(4) Balanced charging of valve-regulated sealed lead-acid batteries: Under normal circumstances, when the valve-regulated sealed lead-acid battery pack encounters one of the following situations, it should be equally charged (if there are special technical requirements, the technical specification of the product shall prevail), and the charging current shall not be greater than 0.2C10.

(1) There are more than two floating charging voltages below 2.18V/piece.

(2) The shelving time is not more than 3 months.

(3) Full floating charging operation for 6 months.

(4) The discharge depth exceeds 20% of the rated capacity.

(5) For high-voltage DC, the server input overvoltage protection problem (282V) should be considered when charging equally.

(5) The charging capacity of the battery is generally not less than 1.2 times the discharged power, and when the charging current is maintained for 3 consecutive hours and does not drop, it is regarded as charging termination.

(6) The float charge voltage of the battery is set according to the requirements of the product technical manual, and the temperature compensation should be paid attention to. Under normal circumstances, the floating charge voltage is 2.23~2.25V (25C, 2V unit), and the floating charge voltage U=U0(25°C)+(25-t)×0.003 (t=ambient temperature) at a certain actual temperature.

(7) The maximum difference between the voltage of each battery in the whole group should not be greater than 90mV (2V), 240mV (6V), and 480mV (12V) during floating charging, and the internal resistance deviation should not exceed 15%.

(8) Battery capacity test and discharge test should be carried out regularly.

(1) A verification discharge test should be done once a year, and 30%~40% of the rated capacity should be discharged.

(2) It is recommended to do a volume test every 3 years

(3) During the discharge of the battery, the unit voltage and discharge current should be recorded at certain intervals.

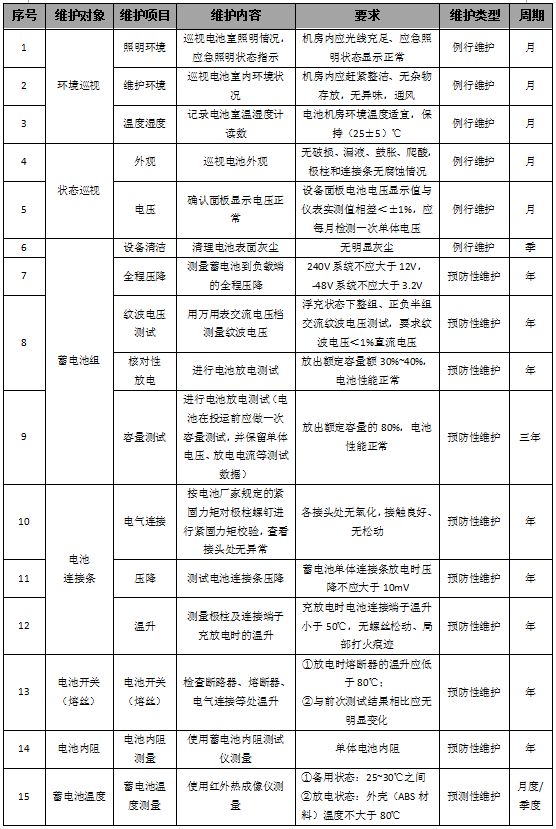

3. Maintenance periodic table:

As shown in Table 3-5, the maintenance cycle table of the battery pack is shown

As shown in Table 3-5, the maintenance cycle table of the battery pack is shown

1. At present, there is no clear regulation on how often the battery in the computer room should be replaced;

2. Enterprises can choose the best replacement time according to their own needs;

3. The replacement time is closely related to the material of the battery, the warranty period, the number of charges and discharges, the change of internal resistance, the temperature, humidity and cleanliness of the battery room, and other environments should be comprehensively considered.

Replacing UPS batteries seems simple, but it is not so easy for an operating computer room, because it involves the safe operation of the computer room, from communicating and determining the plan to receiving materials to organize construction, there is a lot of work to be done, and there can be no mistakes in each construction link. The following is a recent construction project case to describe the preparation and installation process of replacing the UPS battery.

Prerequisites:

1. Approved by superior leaders

2. Formulate corresponding emergency plans and obtain the approval and approval of superior leaders

3. Notify potentially affected customers

4. Notify the general control center

5. The reserve battery is inspected to meet the replacement conditions

6. Implement the management of new and old battery labels

Safety precautions:

1. Construction personnel implement pre-job safety education and training

2. Wear qualified personal safety protective equipment

3. Formulate a special safety manager

4. Prepare corresponding measuring instruments and operating tools, and within the validity period of the instrument tool inspection

Preparation:

1. Organize and determine the installer.

2. Collect the batch of batteries and a small number of spare cables from the warehouse, and transport them to the computer room to remove the battery packaging and place it.

3. Check the battery parameters, check that the appearance is not damaged, and the battery terminal block is not oxidized.

4. Label the battery number in order.

5. Use an internal resistance meter to measure the internal resistance and battery voltage, and record the measurement data of each battery according to the label number.

6. If you switch to the generator for power supply when changing the battery, you need to contact the generator to prevent business interruption caused by unexpected power outage of mains power.

Installation Process:

1. Organize and determine the installer.

2. Collect the batch of batteries and a small number of spare cables from the warehouse, and transport them to the computer room to remove the battery packaging and place it.

3. Check the battery parameters, check that the appearance is not damaged, and the battery terminal block is not oxidized.

4. Label the battery number in order.

5. Use an internal resistance meter to measure the internal resistance and battery voltage, and record the measurement data of each battery according to the label number.

6. If you switch to the generator for power supply when changing the battery, you need to contact the generator to prevent business interruption caused by unexpected power outage of mains power.

Installation Steps:

1. The construction personnel bring installation and testing tools (a set of sockets, adjustable wrenches, screwdrivers, hydraulic pliers, multimeters, etc.) to the construction site of the computer room.

2. Check and confirm that the sleeve handle and wrench handle are well insulated.

3. Plug the generator output wire into the industrial connector of the backup power, start the generator, and let the generator run first.

4. Open the battery cabinet to take pictures and set aside, find the output line connected to the UPS host and confirm the positive and negative poles.

5. Confirm that the generator is running stably, and after the voltage is measured at the input end of the conversion switch in the distribution cabinet, switch the switch to the generator side, observe and confirm that the UPS host is running normally, and disconnect the battery cabinet battery empty.

6. Dismantle the old battery, remove the battery on the battery rack from top to bottom section, remove a screw and wrap the connection wire joint with electrical tape, do a good job of insulation (this step is very important, don't be lazy) to prevent the positive and negative electrodes from touching a short circuit, and danger occurs.

7. Remove all the batteries, place them and start installing new batteries.

8. According to the battery number, starting from 1#, starting from the bottom layer of the battery rack, the position direction is the same as the original, the joint screws must be tightened, the connection line is neat, the bend is consistent, there should be an appropriate gap between the batteries, and the connection process should be strictly to prevent short circuit.

9. After the battery is installed, confirm that the positive and negative poles are correct, measure the total voltage, and confirm that the battery is installed and connected correctly.

10. According to the battery parameters, calculate the charging voltage, measure the UPS output charging voltage, meet the charging requirements of this batch of batteries, close the battery cabinet and open it, check the host charging menu, the battery is already charging.

11. Install the battery cabinet, switch the input of the UPS host back to the mains, and confirm that the input and output voltage of the UPS host is normal. Stop the generator, remove the connecting wires, pack up the tools, load the old battery into the car and prepare to transport it back, and clean up the site.