The air source heat pump (ASHP) heating market is developing rapidly, and its proportion in heating equipment is also rising, and with the application area becoming wider and wider, the challenges are also increasing.

What are the challenges faced by air source heat pumps in alpine regions?

-

Affinity Challenge. Air source heat pumps are mostly used in areas where it is impossible to connect to the municipal heating pipe network, and users have abandoned traditional heating methods such as coal and firewood, and completely rely on electric power source heat pumps for heating. Due to the lack of in-depth understanding, distrust, and panic of electricity bills about air source heat pumps, it has profoundly affected equipment selection, system installation, and later operation methods. The dispersed use of equipment and the difficulty of maintenance and repair are a major challenge for continuous operation and maintenance guarantee and long-term harmonious customer-business relationships.

-

Satisfaction Challenge. Alpine areas traditionally use plumbing radiators at the end of heating, which is a summary of the long-term life experience of northern residents. Mapped to the air source heat pump unit, the widening evaporative condensation temperature difference, the impact of the defrosting process, etc., have become constraints on heating satisfaction.

-

Security challenges. The extreme cold requires higher protection of the main engine and pipelines, and some active anti-freezing measures must be adopted, such as electric heat tracing, electric heating and ice melting, and maintaining the heat of key parts. These active anti-freeze measures rely on a stable supply of electricity and require the understanding and close attention of the user's operators, otherwise a single erroneous power loss will cause the unit to go down.

-

Weathering challenges. The temperature difference between day and night is large, the ultraviolet rays are strong, and the coating on the surface of the equipment, the insulation of pipes, the outer skin of the cable, and the use of wrong plastic parts...... Causes great damage and accelerates aging. Taking pipe insulation as an example, without considering the appearance, mainland installers may use black rubber and plastic insulation and then wrap it with tape, but in high latitudes and high altitudes, it will not take long for the material to age and crack, and protective measures must be strengthened, such as metal skin for external protection.

-

The challenge of rain, snow, wind and frost. The main heat of the air source heat pump is taken from the cold air outside, and frosting and snowmelting are unavoidable problems, and this problem is becoming more and more difficult to solve in alpine areas. The winter wind wrapped the crop fluff, sudden freezing rain and hail...... It may cause the unit to be paralyzed at any time.

To promote the use of air source heat pumps in alpine areas, the following details need to be paid attention to:

-

Adaptability to low temperature conditions: In alpine areas, the heating demand is large, so the heating capacity of air source heat pumps needs to be strong enough to meet local heating needs. This should be fully considered in product design and system design to ensure that the heat pump can operate efficiently at low temperatures. For extreme low temperature environments that are likely to occur, product design and system design should have plans to ensure that they have adaptability to complex working conditions and can provide sufficient heating capacity while maintaining their own stability at low temperatures.

-

Antifreeze measures: In cold regions, the operating effect of the outdoor unit of the air source heat pump is susceptible to freezing. Therefore, it is necessary to strengthen anti-freezing measures, and give priority to passive anti-freezing measures or multiple measures, such as: using split heat pumps to avoid exposure of waterway pipelines to the outdoors; thermal state preservation measures at key parts that combine heat generation and phase change heat storage; antifreeze is used for thermal fluids, etc. Ensure safe operation of heat pumps in the most demanding conditions.

-

Thermal insulation protection: In extremely low temperature environments, the impact of system heat loss on heating capacity will be more pronounced. Pipes, water tanks and other components of the heat pump system are prone to freezing and causing system failure. Therefore, it is crucial to repeatedly emphasize the thermal insulation protection of the system, strengthen the insulation measures of the system, and keep the insulation system intact.

-

Humidification function: For users who use air pans and hot air fans as terminal heat dissipation equipment, the indoor temperature may be dry due to the low air humidity in alpine areas. Therefore, the humidification function should not be omitted in the product design or system design to make the indoor environment more comfortable.

In short, reasonable design and full consideration of these details will help improve the performance and reliability of the heat pump system and ensure normal operation in cold environments.

The performance characteristics of air source heat pumps suitable for use in alpine regions should be:

-

High-efficiency jet enthalpy enhancement technology

Iterative improvement, fully tap the potential of jet enthalpy enhancement technology, and adopt a new enthalpy enhancement branch design to ensure that the enthalpy enhancement branch of the unit absorbs liquid phase refrigerant at multiple points at ultra-low ambient temperature, so as to further break through the ultra-low temperature operation limit and stabilize heating. -

A new generation of evaporators

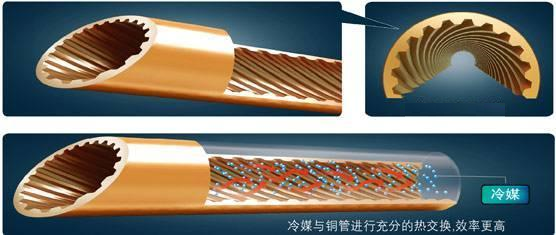

It is necessary to further strengthen the internal heat exchange of the high-cold air source heat pump, reduce the difference between the condensation temperature and the evaporation temperature that should be expanded due to insufficient heat transfer driving force, and improve the efficiency of the main engine. Because the lower ambient temperature corresponds to the lower refrigerant vapor pressure, the flow rate of the vapor phase part in the evaporator pipeline increases, but at the same time, it is limited by frictional resistance and sound speed, which will cause the heat transfer efficiency of the inner wall of the evaporator pipe to not be fully utilized. Therefore, it is necessary to choose a new type of tube for the evaporator, which is more conducive to working in alpine areas than the traditional reinforced heat exchanger tube with trapezoidal groove or the fluorescent tube adopted earlier.

-

Precise defrosting and snow melting technology

Reformulate targeted defrosting and snow removal strategies suitable for alpine regions, and use new visual sensors and AI intelligent algorithms to accurately defrost and snow to ensure efficient and stable heating of units. Experience shows that sometimes the seemingly outdated technology of electric defrosting may be ideal in alpine regions.

-

Intelligent control

It has the ability to analyze and process historical operation data, and gives response plans or warnings after analysis of overload operations, so as to minimize the possibility of machine failure. After the operation parameters and the unit vibration and sound data collected according to the policy are uploaded, the professional software analyzes and predicts the fault, and the possible faults are intelligently resolved.

The system design and installation process of air source heat pump heating system suitable for alpine regions should pay attention to:

-

At this stage, although air source heat pump heating projects in alpine regions are growing rapidly, the total number of successful cases and selection practices that can be used as a reference cannot meet the changing application needs. System performance, comfort, and energy efficiency can be affected by usage scenarios and poor system design choices. Operational guidelines should be formulated to guide installers to reasonably determine and select air source heat pump products and their system solutions, while taking into account high energy efficiency, giving full play to unit performance and customer satisfaction.

-

For existing buildings that purchase air source heat pumps as heating equipment, field surveys should be conducted to fully understand the problems of the building envelope and the remaining problems of the past heating system, such as: the actual heating area and floor height of the building, the insulation situation, air leakage, and the disconnection/leakage of existing pipes. Legacy issues need to be addressed before new equipment is installed, which not only avoids project risks, but also reduces the required equipment specifications, reduces heating and cooling costs, and maximizes heat pump performance and comfort.

-

Calculate the load correctly. Whether it's a single area or an entire home, oversized equipment can lead to excessive circulation and inefficiencies. In addition to referencing data from relevant HVAC standards, other acceptable methods for calculating heating and cooling loads are more often used for air source heat pump installations. In some cases, the contractor uses a simplified load calculation method. The method that is closer to reality is to understand the previous heating situation with the customer on site as the basis.

-

The location of the outdoor unit should be agreed by the customer. For aesthetic and noise reasons, outdoor units should be installed in an inconspicuous place, such as the rear of a building. At the same time, the outdoor unit unit should be installed where the air flows freely, and the cold air that has been squeezed out of excess heat should naturally "flow" to a distance. Remove obstacles in accordance with the manufacturer's quality standards, including walls, overhangs, protrusions, etc. Ensure that the outdoor unit does not interfere with the view or operation of windows or doors.

-

The outdoor unit should be placed horizontally on the left and right, front and rear, and be raised to ensure that it is above the historical average maximum snow depth. The value of the catch tray heater may be limited, the slope is more important, and the water in the catch tray should easily enter the drainage system to prevent ice buildup from forming. Avoid installing outdoor units directly under the drip line of the roof or other suspensions so that they are not affected by snowmelt, ice, or rainfall runoff. When outdoor units are installed unavoidably and there are no normal operating drains, outdoor equipment must take protective measures according to local conditions.

-

System designers and installers should follow the manufacturer's instructions for minimum and maximum pipe length and height variations, and refrigerant charge should be adjusted only when necessary. The test process should follow the work instructions, and test whether there is any leakage in the seal of the pipeline device by using dry nitrogen and vacuum pump three times of evacuation. I would also like to give a tip of thumbnail here: do not use flare fittings for extension pipes unless necessary, and try to use seal crimps designed for refrigerant and tubing types for pipe connections.

-

When installing an air source heat pump system using existing piping, it is important to ensure that the ductwork is sized to meet the heat pump air flow requirements and the available static pressure. When the head of the circulating pump had to be increased to meet the flow demand, the pressure capacity of the old line needed to be reassessed.

-

The insulation must cover the entire length of the line group (two pipes) to the roots of the pipes, avoiding condensation and energy loss. UV-resistant tape or other mechanical protection should be installed on the outside to ensure that other exposed insulation is protected. The wire set through the building envelope must be resistant to rodent gnawing and drilling (e.g., PVC sleeves and covers, or sealing with metallic wool padding or similar materials). Finally, foam seals the visible gaps to prevent the building's sealing performance from being weakened by the installation of heat pumps.

-

The thermostat must be installed in a position that represents the comfortable temperature of the space being served, away from direct sunlight, appliances, or ventilation. For remote monitoring needs, the reliability of wireless signal transmission needs to be repeatedly tested.