Real scene between cylinders:

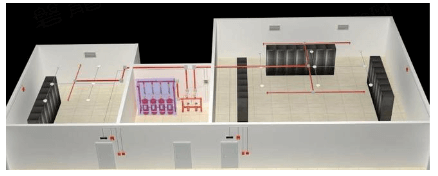

Application scenario diagram:

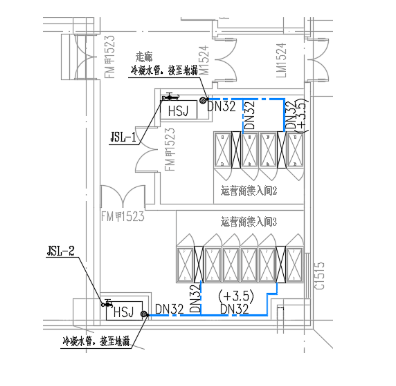

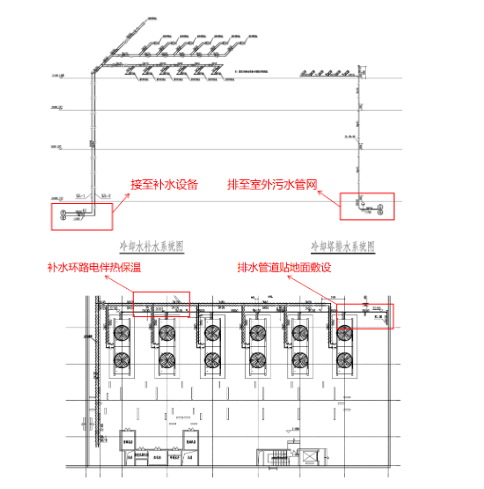

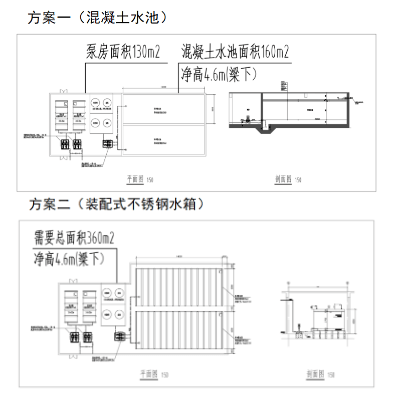

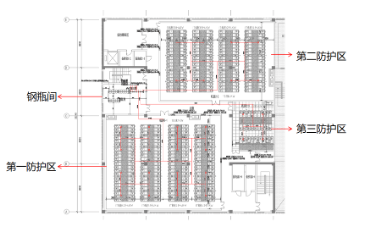

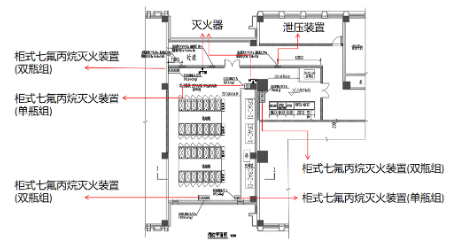

Examples of cabinet heptafluoropropane gas fire extinguishing system design are as follows:

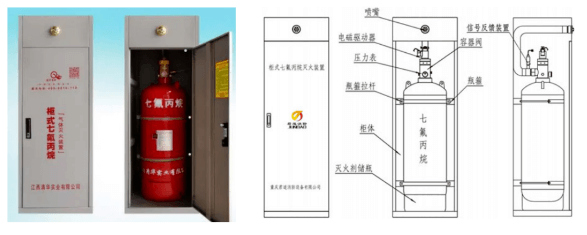

Illustration of cabinet type heptafluoropropane gas fire extinguishing device:

Pressure relief port settings:

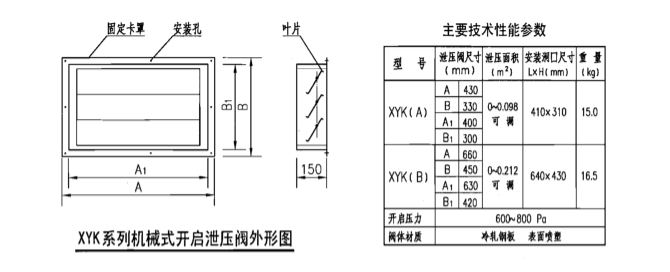

According to Article 3.2.7 of the Design Code for Gas Fire Extinguishing Systems GB50370-2005, pressure relief ports should be provided in the protected area. For safety reasons, the same protective area should use pressure relief ports of relevant specifications, and pressure relief ports should be evenly distributed on the wall that can relieve pressure. The lower edge of the pressure relief port is not less than 2/3 of the net height of the protection area, and it is recommended to install the upper edge of the beam. Usually a mechanical pressure relief valve is used, and the pressure relief area is adjustable, as shown below:

Matters to be paid attention to in fire renovation:

1) According to Article 3.2.4 of the Design Code for Gas Fire Extinguishing Systems GB50370-2005, when using a pipe network fire extinguishing system, the area of a protective area should not be greater than 800 square meters, and the volume should not be greater than 3600 m³; when using a prefabricated fire extinguishing system, the area of a protective area should not be greater than 500 square meters, and the volume should not be greater than 1600 m³.

2) The protection distance of the pipe network type heptafluoropropane gas fire extinguishing system is short, and it is often used in small protection areas, independent protection areas, and places where the distance between cylinders and the protection area is close. IG541 gas fire extinguishing system has a long protection distance and is often used in large-scale projects and large-scale combined distribution projects. The heptafluoropropane system is initially selected in the engineering design, and the length of the conveying pipeline is the distance from the outlet of the decompression orifice plate to the farthest sprinkler, and its range is 40~60m. The IG541 system is preliminarily selected, and the length of the conveying pipeline is the distance from the outlet of the decompression orifice plate to the farthest nozzle, and its range is 70~90m for the primary filling system. The secondary charging system is 100~120m.

3) The cabinet type heptafluoropropane gas fire extinguishing device can be arranged according to the protection radius not greater than 7.5m. The total number of cabinets required can be distributed evenly according to the protection distance.

Fire extinguisher design requirements:

1) According to Article 3.1.2 of the GB50140-2005 Code for the Configuration and Design of Building Fire Extinguishers, the fire in the computer room area and substation room in the data room belongs to Class E fire (live fire).

2) The danger level of the fire extinguisher configuration site of industrial buildings should be divided according to the fire risk of production, use and storage of items, the number of combustibles, the speed of fire spread, the difficulty of extinguishing and other factors. The computer room area, power battery room, transformer and distribution room, etc. are considered according to the serious risk level, and the rest of the parts are considered according to the medium risk level.

3) For details on the selection of fire extinguisher types, please refer to Article 4.2.5 of the specification, and Class E fire sites should choose ammonium phosphate dry powder fire extinguishers and carbon dioxide fire extinguishers, but carbon dioxide fire extinguishers equipped with metal horn barrels should not be selected.

4) In summary, the fire extinguisher configuration in the machine room area is designed according to the serious risk level of Class E fire, using a 30kg trolley carbon dioxide fire extinguisher, with a maximum protection distance of 18m; There are no less than two computing units in one unit. The substation and distribution room, battery room, etc. are equipped with fire extinguishers according to the serious danger level E fire, and 2 portable ammonium phosphate salt dry powder fire extinguishers of 3A class 5kg are placed in each place, with a maximum protection distance of 15 meters, and two are set at each setting point; The rest of the parts are equipped with fire extinguishers according to medium-risk Class A fire places, and two 2A 4kg portable ammonium phosphate salt dry powder fire extinguishers are placed in each place, with a maximum protection distance of 20 meters, and two are set up at each setting point.

Fire extinguisher arrangement:

1) The fire extinguisher should be set in a place where the location is obvious and easy to access, and shall not affect the safe evacuation.

2) The placement of the fire extinguisher should be stable, and its nameplate should be facing outward. The portable fire extinguisher should be set in the fire extinguisher box or on the hook or bracket, and the height of the top from the ground should not be more than 1.50m, and the height of the bottom from the ground should not be less than 0.08m. The fire extinguisher box must not be locked.