Under the trend of "dual carbon", how to build a zero-carbon data center should focus on "where does the electricity come from?" Where is it hot?"

Publication Date:2023-09-04

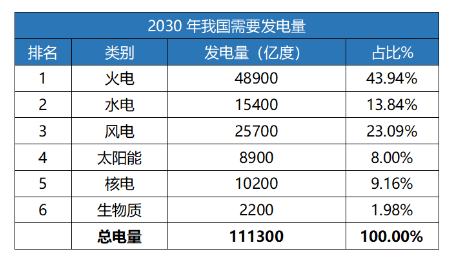

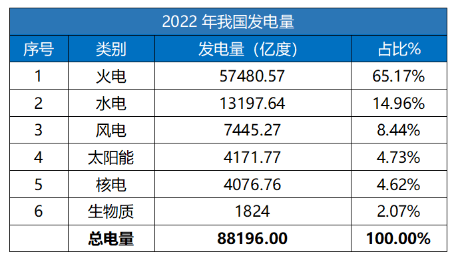

Then compare the 2022 national electricity consumption data from the National Energy Administration, as follows:

The key to whether the refrigeration system can save energy is whether it can effectively use the natural cooling source, and making full use of the natural cooling source is also the most direct solution to reduce cooling energy consumption and reduce cooling carbon emissions. For example, the annual average temperature of Ulanqab is 5°C~7°C, the annual average temperature of Ningxia Zhongwei is 4°C~18°C, the annual average temperature of Qingyang, Gansu Province is 5°C~13°C, the annual average temperature of Yangquan in Shanxi is 6°C~18°C, and the annual average temperature in Zhangjiakou is 4°C~16°C. The average annual temperature in these areas is more suitable for building data centers, so the "East Data and West Computing" data center cluster prefers the above areas. In addition to the climate, you can also consider places with unique water resources, such as the Three Gorges Data Center Cluster in Hubei Province, which uses the electricity of the Three Gorges to provide computing power and the water resources of the Three Gorges to provide cooling of air conditioners. Data center clusters like this also include the Dongjianghu data center cluster in Binzhou City, Hunan Province, which also uses high-quality water resources downstream of Dongjianghu Dam as a cooling solution to reduce PUE.

At present, the main natural cold source utilization schemes in data centers are as follows:

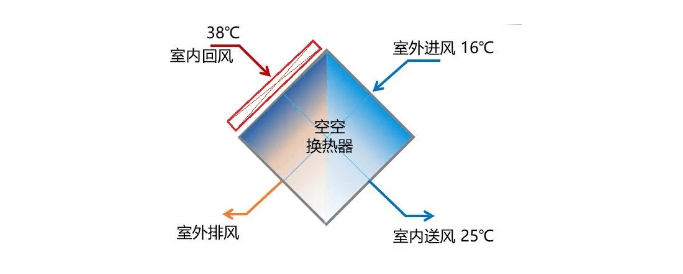

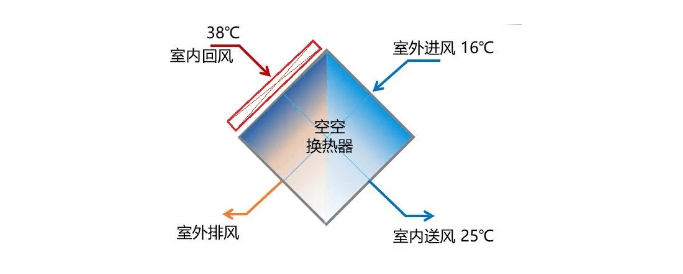

(1) Indirect evaporative natural cooling unit (AHU) scheme

Indirect evaporative cooling energy-saving unit is an equipment that makes full use of the natural cooling source of the atmosphere to achieve heat dissipation in the data room through the heat exchanger of the hot core (air-air heat exchanger), and the indoor/outdoor air can be transferred without mixing and exchanging, minimizing the use time of mechanical refrigeration, so as to achieve energy saving, low-carbon and environmental protection. At the same time, the AHU unit uses the principle of water evaporation and heat absorption on the outdoor side to spray water (mist) on the outdoor air, further reducing the temperature of the outdoor air (lower than the outdoor ambient temperature), thereby extending the utilization time of the outdoor natural cooling source and achieving the purpose of energy conservation and consumption reduction. It is usually deployed on the roof or side of the data center and is ideal for new construction, renovation of large, medium and large data centers.

The AHU indirect evaporative cooling unit scheme is an integral structure and the system is simple. Compared with the traditional water-cooled chilled water system, this unit scheme integrates cold source equipment, transmission and distribution equipment, unfinished equipment, and automatic control system, which is very convenient for later maintenance. The second feature is flexible deployment and shortened construction cycle. The third feature is water and electricity saving, which can reduce operating costs. The unit solution can make full use of the outdoor natural cooling source, reduce the compressor start time, and the operating modes are divided into dry mode, wet mode and mixed mode. In dry mode and wet mode, the compressor does not turn on. In mixed mode, the compressor is partially turned on. Run dry mode when the temperature is relatively low in winter, and there is no need to spray water when running dry mode. The WUE of the traditional chilled water system is between 1.8~2.4 and the WUE of the AHU system is between 0.3~0.8.

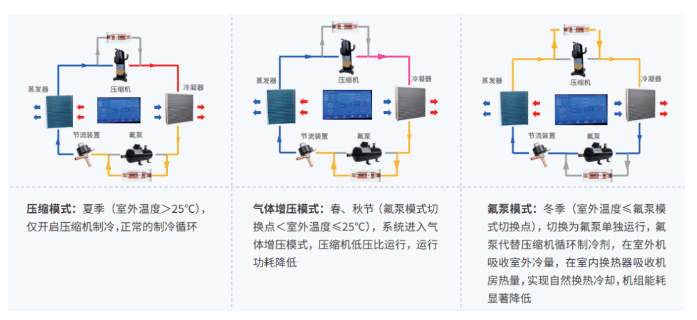

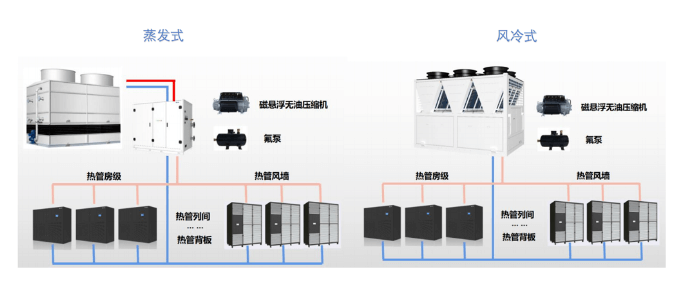

(2) Fluorine pump series natural cooling air conditioners

The development of fluorine pump technology has been more than ten years, and the application of fluorine pump technology in data centers is a relatively common technology. The current fluorine pump air conditioning system includes: fluorine pump air conditioner, magnetic levitation phase change multi-unit air conditioner, PHU integral fluorine pump unit, fluorine pump multi-unit air conditioner and other main forms. No matter what form of fluorine pump air conditioner, its basic principle is similar, the fluorine pump system uses the refrigeration compressor to run cold, in the spring and autumn transition season to use the fluorine pump and compressor "mixed mode" operation, and the fluorine pump natural cooling mode is turned on in winter to ensure the safe and reliable operation of the air conditioner in the machine room throughout the year. The biggest advantage of fluorine pump series air conditioners is that they use natural cooling sources, and can be applied to drought and water shortage scenarios.

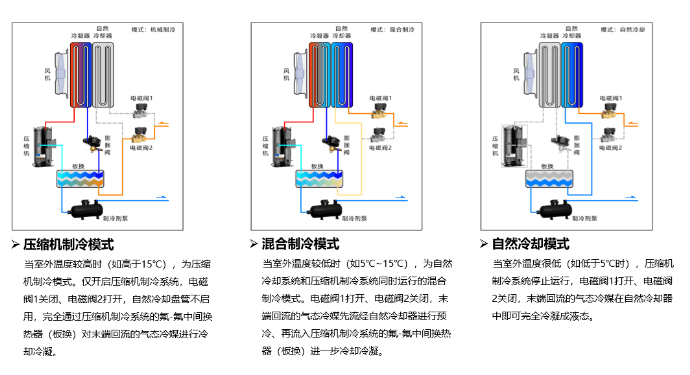

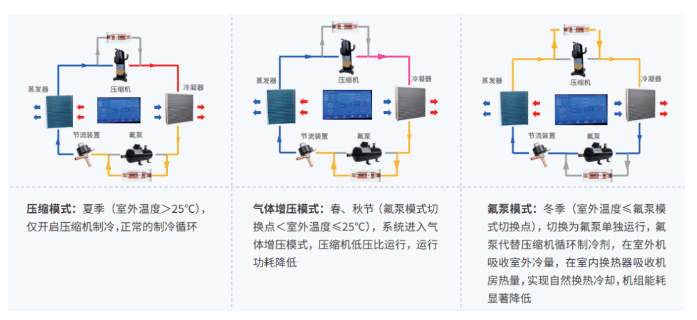

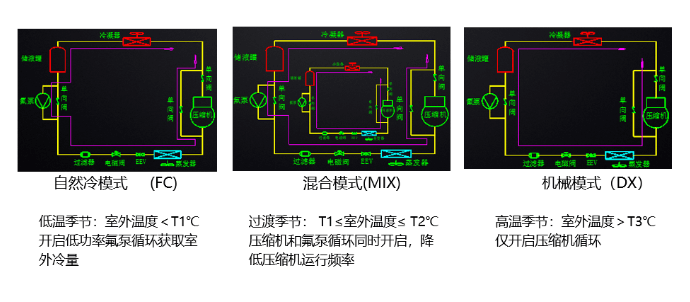

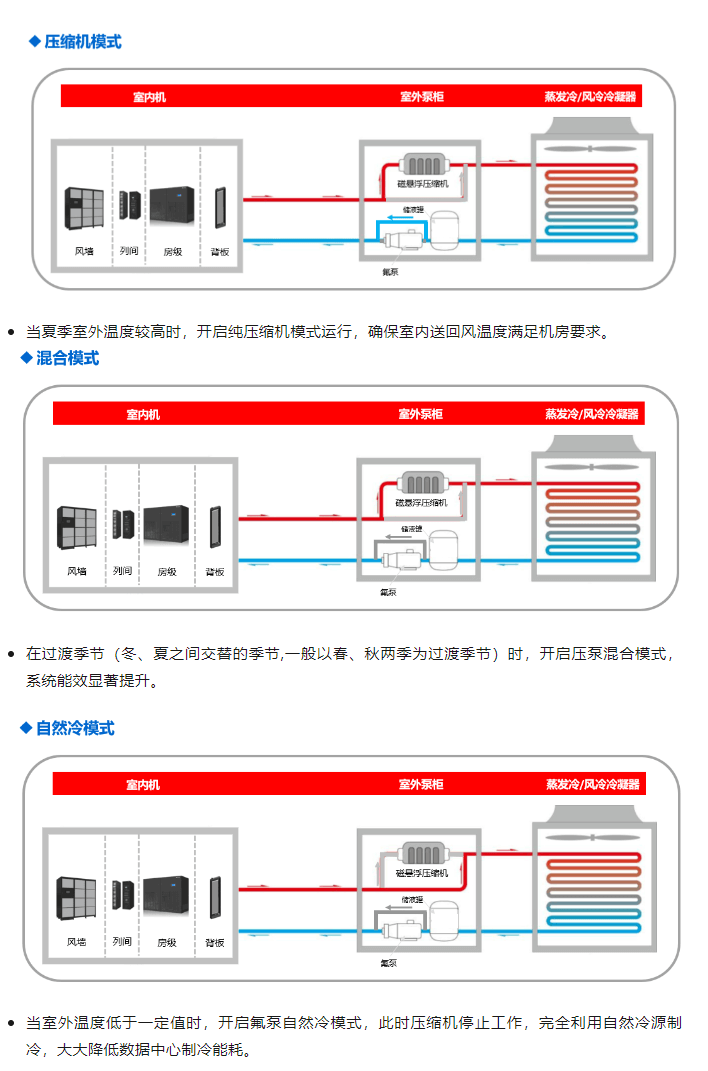

At present, the most mature product in fluorine pump technology is the gas-boosted fluorine pump unit, which is designed for indoor and outdoor units separately, with flexible configuration and suitable for data center scenarios of various sizes. The fluorine pump unit system has three operating modes and makes the most of the outdoor natural cooling source, such as Haiwu's fluorine pump unit, which operates as follows:

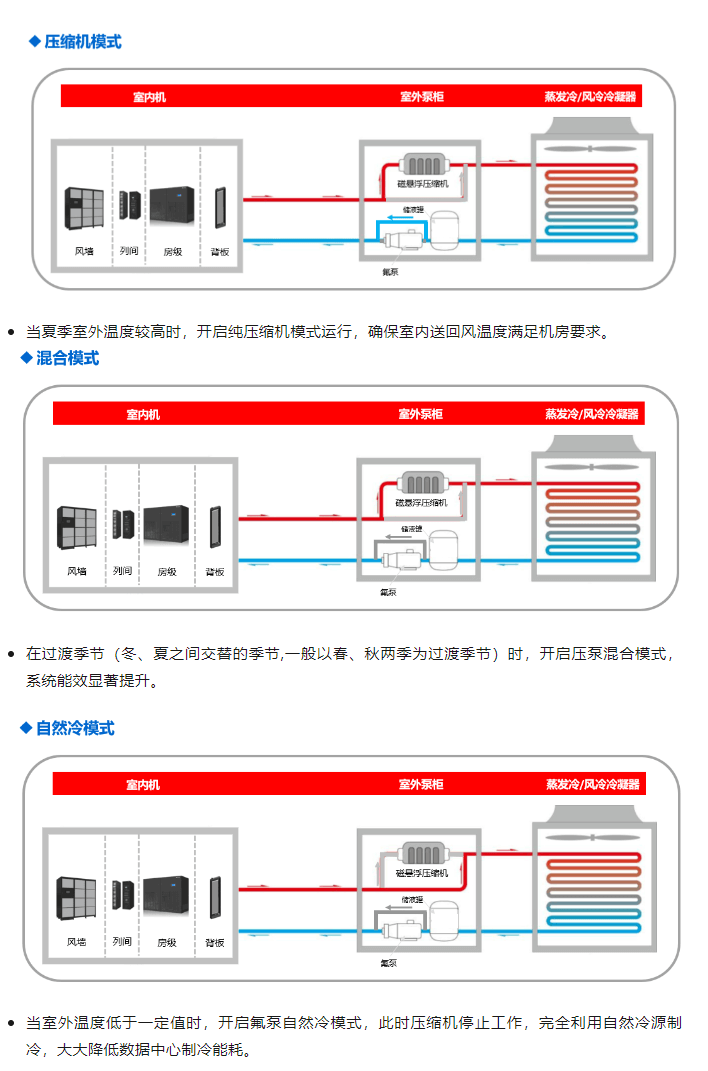

In addition to split fluorine pump units, in recent years, integral fluorine pump unit solutions (PHUs) have emerged, which are cooling solutions for large-scale data center scenarios. PHU integral fluorine pump air conditioning unit is an integrated equipment that makes full use of natural cooling sources through low-power fluorine pumps to realize data center cooling, and also has three operating modes, which can maximize the energy efficiency ratio of the refrigeration system by automatically switching the operating mode by monitoring the outdoor ambient temperature. For example, the PHU unit operation mode of Haiwu is as follows:

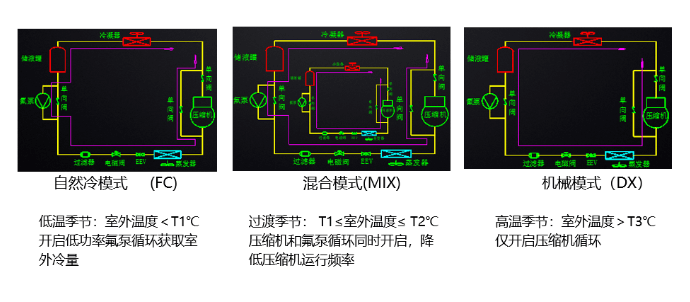

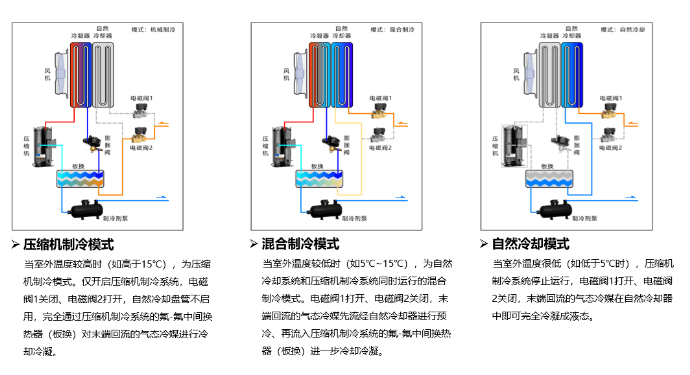

The magnetic levitation phase change multiplex system also has three operating modes, such as the Haiwu magnetic levitation phase change multiplex system, and its operating principle is as follows:

(3) Natural cooling of the water source at all times

Using the water sources of natural rivers, rivers, lakes and seas to provide cooling water for the data center, it can cool the water source without consuming electricity, and the water source can be naturally cooled almost most of the time throughout the year, greatly reducing the annual PUE of the data center.

The most critical point of this solution is the location of the data center, which needs to be selected close to the natural water source, by pumping river or lake water, and directly used as cooling water after simple filtration, because the temperature of river water and lake water is usually more than ten degrees Celsius, which is much lower than the air temperature, and the temperature fluctuation in the four seasons is very small, which can effectively take away the heat generated by the server. The specific implementation method is to pump up the river or lake water and filter it, and then introduce it into the cooling water pipeline of the data center, and carry out secondary heat exchange through the plate replacement and the data center air conditioning chilled water, the return water temperature of the chilled water is usually 21 °C, and after the plate replacement, it is cooled to 15 °C to cool down the air conditioner. After the temperature of the lake water is changed by the plate, it is discharged into the river, so as to transfer the heat of servers and other equipment to the river water to achieve the purpose of cooling. When designing the scheme, it is necessary to consider factors such as water quality, flow rate, and temperature of the water source to ensure the cooling effect and equipment safety.

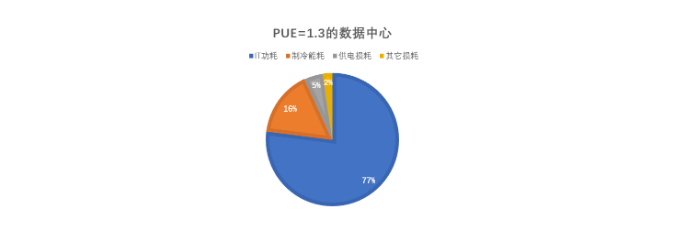

The more famous data center with lake water cooling is the Alibaba Hangzhou Qiandao Lake Data Center, which uses deep lake water, and there are two lake water processors outside the data center, which draw water from a depth of 35 meters below the lake surface through sealed pipes, and the water temperature is basically maintained at about 10 degrees. After the buffer tank enters the lake water processor, and then enters the data center, through the board exchange and frozen water for heat exchange to help the server cool down, and then flows through the 2.5-kilometer Qingxi New Town Central Axis Creek, which is presented as an urban landscape, and finally flows back to Qiandao Lake. The data center achieved an average annual PUE of 1.3.

The more famous case of using Yangtze River water cooling is the Dongjianghu data center in Zixing City, Hunan Province. The Dongjiang Lake Data Center uses the river water downstream of the Dongjiang Lake Reservoir dam as a natural cooling source, the river water temperature downstream of the dam is 8~13 °C all year round, and the river flow is stable and the water quality reaches the national first-class standard. After heat exchange, the river water is discharged downstream through a closed pipe, and the whole process does not consume water resources and does not affect the water quality of the river. This cooling method can reduce the energy consumption of data centers, requiring only one-fifth of the energy consumption compared to traditional cooling methods to ensure the normal operation of the facility. Dongjianghu data center is completely cooled by river water sources for 99% of the year, and almost no chillers are started throughout the year. The river water is cooled at full time, and the average annual PUE is 1.15.

3. Application of liquid cooling technology scheme

Innovative technology is the core driving force to promote energy conservation and carbon reduction in data centers, the innovation of cooling methods, and the optimization of design and construction methods. In the field of data centers, the number of servers determines the business processing capacity of the entire data center, while medium and large data center servers are calculated in thousands, and 10 servers are placed in a rack, and a large data center needs hundreds of racks. Such a huge amount of server equipment running at the same time, calculated according to the operating power of 300W per unit, 10,000 units will cost 3 megawatts, so if each server can save a little energy consumption, the energy consumption saved by 10,000 servers is very considerable. Therefore, many experts start from the server, work the server, and try to reduce the energy consumption of the operation and improve the operating environment of the server without reducing the operating performance of the server. Compared with the volume of air and water, such as 1 cubic of water and air, when the temperature changes by 1°C at room temperature, the heat transfer of air is about 1.3 kilojoules, and the heat transfer of water is about 4200 kilojoules, which shows that the heat transfer capacity of water exceeds 3000 times that of air.

At present, liquid-cooled data centers in our country are still in a stage of rapid development, but some large enterprises and institutions have begun to try to deploy liquid cooling technology, such as Alibaba, Tencent, Huawei and other companies are building or transforming some data centers into liquid-cooled data centers. In addition, some startups are also exploring and practicing in the field of liquid cooling, such as Yunku Intelligence, Green Yuntu, Yimikang, Haiwu, Shenling, etc.

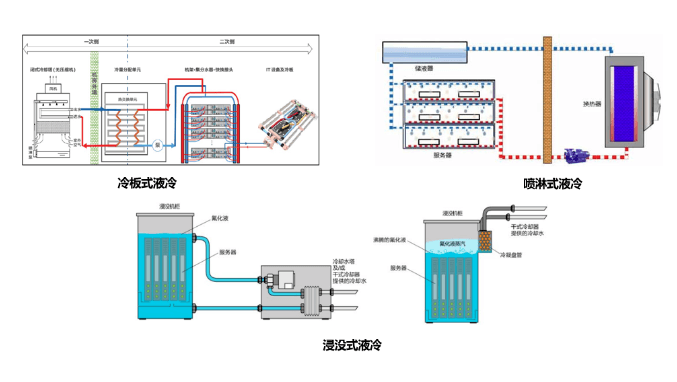

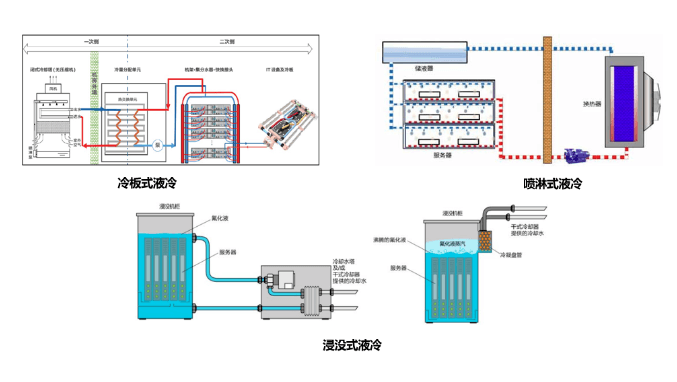

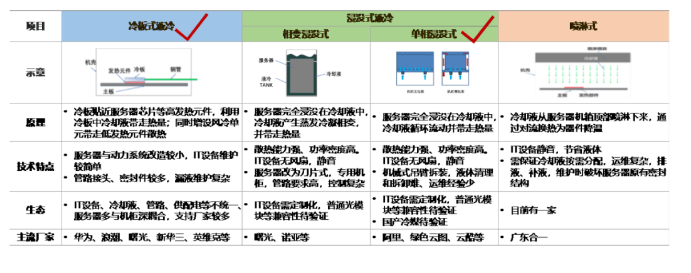

At present, there are three main categories of liquid cooling technology, namely spray liquid cooling, immersion liquid cooling, and cold plate liquid cooling, and the schematic diagram is as follows:

1. Spray liquid cooling: Spray coolant on the cooling elements of the server by spraying to remove the heat generated by the server.

2. Immersion liquid cooling: A cooling system that completely immerses the heating components of the server in the coolant and takes away the heat of the server through the convection or phase change of the coolant. According to the current mainstream fluoride solution, the single-phase heat exchange capacity of fluoride liquid is more than 1200 times that of the same volume of air. If the phase change immersion type is adopted, the phase change heat transfer capacity of the fluorinated liquid is more than 10,000 times that of the same volume of air.

3. Cold plate liquid cooling: Liquid cooling cold plate heat dissipation is used for large-power components such as CPU in servers, and air cooling systems are still used for other heat-generating devices (such as hard disks, interface cards, etc.). The advantage of cold plate liquid cooling is that it has little impact on the architecture of the existing computer room, and the heat dissipation capacity of water is 3200 times that of the same volume of air, and it has the characteristics of low noise, high space utilization and heat energy recovery.

According to the research data of CCID Prospective Industry Research Institute, the market size of our country's liquid cooling market in 2022 will be about 60 billion yuan, of which the market share of cold plate liquid cooling will account for about 65%, and the submersible liquid cooling will account for about 34%, and the liquid cooling market size of our country will increase to 80 billion yuan in 2023, and the liquid cooling market size of our country is expected to reach about 130 billion yuan by 2025.

In 2018, Alibaba built a large-scale immersion liquid-cooled Zhangbei data center, which is Alibaba Cloud's first data center to apply a fully immersion liquid-cooled server, which has a heat conduction efficiency of 100 times higher and an energy saving effect of more than 70% compared with traditional refrigeration systems. Alibaba Zhangbei liquid-cooled data center not only has technological innovation and leading edges, but also pays attention to environmental protection and energy saving. The data center uses advanced energy-saving technologies such as natural cooling to control the power utilization effectiveness (PUE) within 1.25 and as low as 1.13.

The advantage of immersion liquid cooling technology is not only heat conduction and heat dissipation, but also the ability to accommodate more IT equipment and improve computing power. The power density of Alibaba Zhangbei liquid-cooled data center reached 60 kilowatts, increasing the computing density by 10 times. At the same time, the liquid-cooled cabinet has the characteristics of high sealing, which keeps electronic components away from the influence of humidity, dust and vibration, improves the stability of the equipment and reduces the incidence of failure. In the past three years of operation, the failure rate of Alibaba Zhangbei liquid-cooled computer room has been reduced by 54% compared with other computer rooms of the same size. Based on Alibaba's experience with Zhangbei liquid-cooled data center, in 2020, Alibaba built China's first 5A-level liquid-cooled data center in Hangzhou - Alibaba Hangzhou Renhe liquid-cooled data center, which uses fully immersed liquid-cooled servers in the entire building. Due to the large-scale use of fully immersion liquid-cooled server technology, the overall PUE value is 1.09, which is currently the world's leading level.

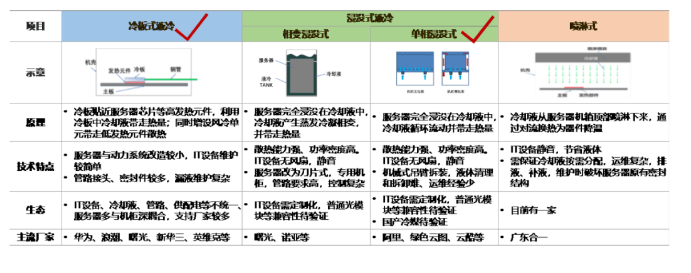

On June 5, 2023, the three major operators of China Mobile, China Unicom and China Telecom released the "White Paper on Liquid Cooling Technology for Telecom Operators" at the "Computing Power Innovation and Development Summit Forum" of the 31st China International Information and Communications Exhibition, which analyzed the current situation faced by data centers and the development status of liquid cooling technology, introduced the practice and current development challenges of liquid cooling technology of telecom operators, and put forward the three-year vision and specific technical route for the development of liquid cooling technology of telecom operators. The selection of two key technologies of cold plate type and immersion liquid cooling is introduced. On the whole, cold plate liquid cooling and single-phase immersion liquid cooling have their own advantages and disadvantages, and the ecology needs to be improved, and the evolution of both will take time, and will coexist and develop in a certain period of time in the future, which is the mainstream of development in the current industry. In summary, telecom operators are currently promoting two technical routes: cold plate liquid cooling and single-phase immersion liquid cooling, as detailed below:

According to the White Paper on Liquid Cooling Technology for Telecom Operators, it is expected that more than 50% of data center projects will use liquid cooling technology by 2025. Liquid-cooled data centers in the Internet industry account for 24.0%, the financial industry accounts for 25.0%, the telecommunications industry accounts for 23.0%, and the energy industry accounts for 10.5%.

The emergence of liquid cooling technology not only contributes to the "dual carbon" strategy, but also promotes the implementation of new energy-saving technologies in data centers, improves the heat dissipation form of traditional air cooling, and can better meet the needs of high-density cabinets, chip-level precise cooling, more energy-saving, more land-saving, and lower noise.

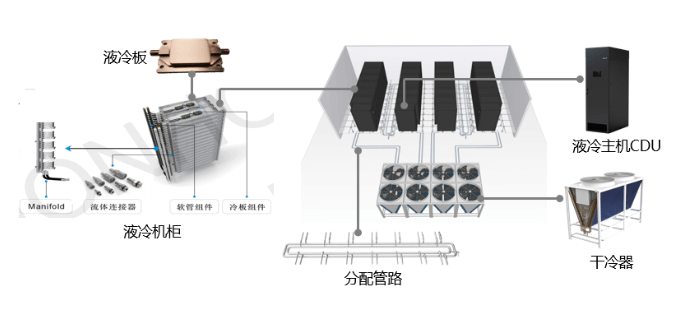

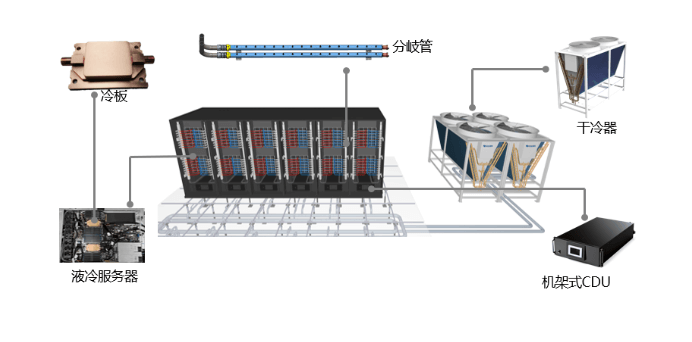

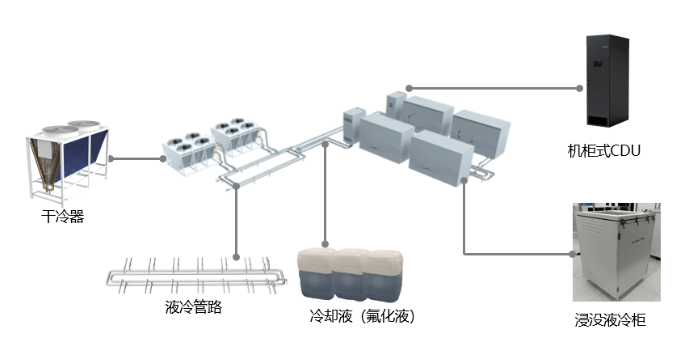

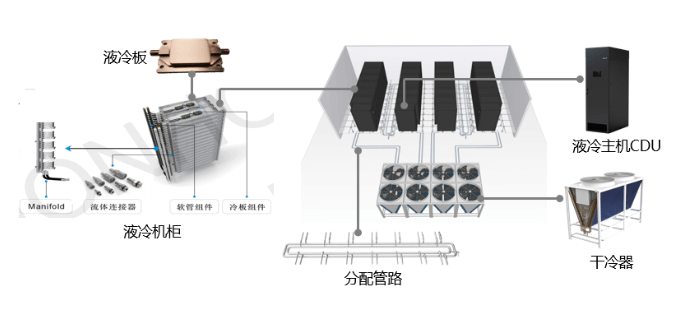

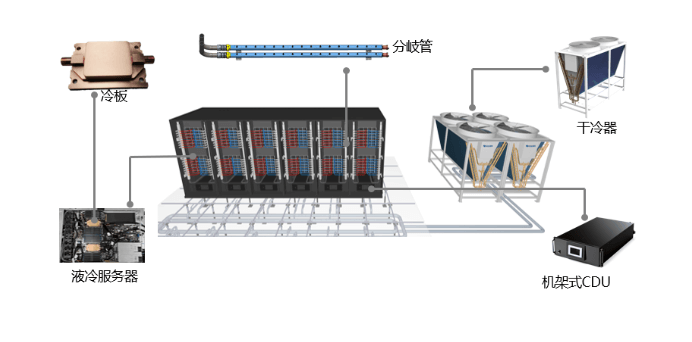

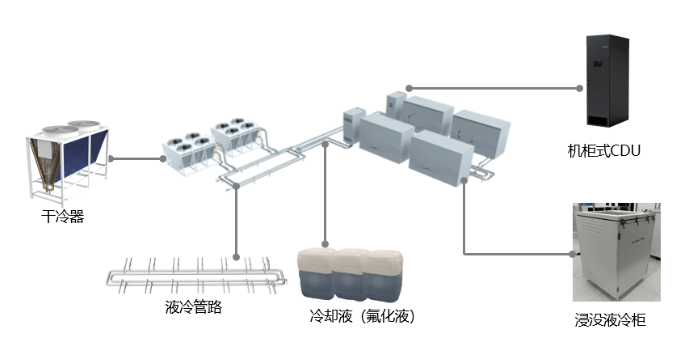

In the actual data center scenario application, the liquid cooling solution is combined with different products to formulate scenario-based solutions, such as Haiwu's scenario-based liquid cooling solution, namely:

Scenario 1: Using cold plate liquid cooling, with centralized CDU solution, the maximum power density supported by this solution is 50~80kW, and the average annual PUE of the overall liquid cooling solution can be 1.2 and below.

Scenario 2: This scheme adopts cold plate liquid cooling, with distributed CDU scheme, the maximum supported power density of this scheme is 50~80kW, and the average annual PUE of the overall liquid cooling scheme can also be 1.2 and below.

Scenario 3: This solution adopts single-phase immersion liquid cooling, outdoor dry cooler, and dual cabinet CDU, with a maximum supported power density of 30~100KW, and the average annual PUE of the overall liquid cooling scheme can be 1.1 and below.

At present, the solutions of various liquid cooling equipment manufacturers are different, because the current ecology of liquid cooling technology is not perfect, the product forms are different, the degree of product standardization is low, the cabinet and the server are deeply coupled, and there is no unified interface standard, which is difficult to standardize and promote and apply on a large scale. To promote liquid cooling technology, it is necessary to brainstorm and build consensus, improve the standardization and ecological construction of the liquid cooling industry, promote the orderly development of liquid cooling technology, and open up a high-quality development path for the data center liquid cooling industry.

4. Application of heat recovery scheme

With the advancement of the "dual carbon" policy, more data center practitioners have focused on the waste heat of the data center, which is a high-quality heat source that can be used to heat domestic water and heating, and can indirectly reduce carbon dioxide generated by the use of fossil fuels while helping users reduce heat costs. According to existing data, the total recoverable waste heat of data centers in our country's northern region is about 10GW, which can theoretically support 300 million square meters of building heating. At present, some large data centers have adopted data center waste heat recovery technology, such as Alibaba Qiandao Lake Data Center, Tencent Tianjin Data Center, China Telecom Chongqing Cloud Computing Base, GDS Beijing No. 3 Data Center, and Ucloud Ulanqab Cloud Computing Data Center. The use of waste heat recovery technology for heating and hot water in the park can not only reduce energy consumption, but also reduce the operating costs of the data center, which can be described as killing two birds with one stone.

At present, the main schemes of waste heat recovery include the following:

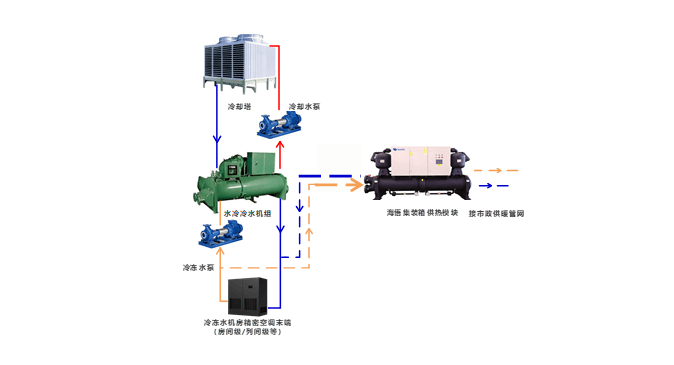

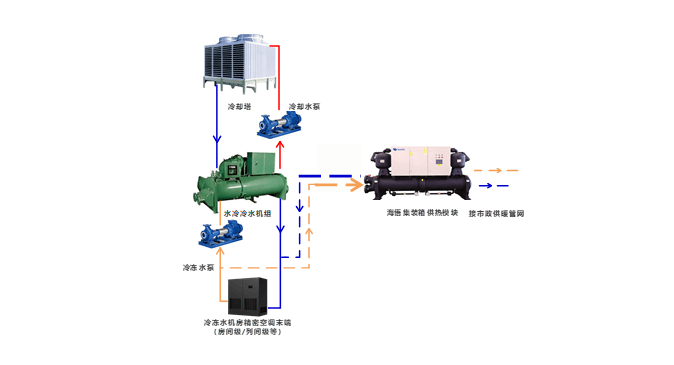

(1) Waste heat utilization of the air conditioning system of the chilled water computer room

The refrigeration process of the air conditioning system of the chilled water room is as follows: the chilled water pump brings the heat in the machine room into the cold evaporator through the water circulation, the compressor transfers the heat absorbed by the evaporator to the condenser under the electric drive, the cooling water pump pushes the water circulation to exchange the heat of the condenser and bring it to the cooling tower, and the cooling tower dissipates the heat in the circulating water to the outdoor environment through forced heat exchange through direct or indirect means. And so on.

The air conditioning system of the chilled water machine room is usually less energy efficient throughout the year, and generally adopts the waste heat recovery of the chilled water side, and the system principle is as follows:

Waste heat recovery mainly occurs in winter, through the waste heat recovery unit for heat recovery, and then heats the surrounding buildings.

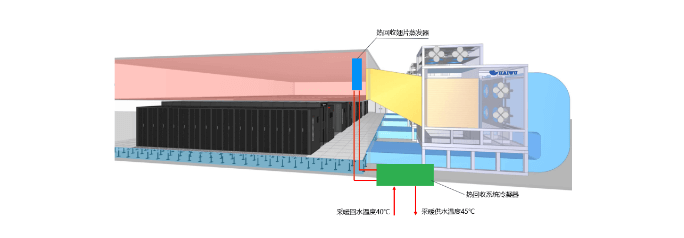

(2) Waste heat recovery from the return air of the AHU air conditioning system room

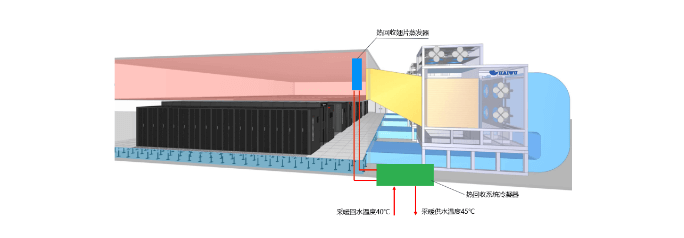

AHU air conditioning system is a temperature control method widely used by large data center computer rooms, especially in the northern region, which can make good use of the natural cooling source and greatly reduce the PUE of year-round operation. The rest of the heat recovery principles are as follows:

Here (the return air side of the heat exchange core of the AHU unit) has a higher heat grade and the best recovery effect. Then, the air-air heat exchanger in the AHU unit is exchanged with the outdoor air, and the AHU can automatically adjust the outdoor cold air entering the air-air heat exchanger according to the indoor return air temperature.

According to the calculation of the operating parameters of Haiwu AHU products, the heat recovery method only needs to install a fin evaporator in the return air cavity of the computer room, the temperature of the return air into and back heat evaporator is 38 °C, the temperature of the evaporator is 26~28 °C, and the usable temperature can reach more than 10 °C, and the maximum wind resistance of the fin is only about 40 Pa. The total power consumption of AHU fans increased by about 0.85kW, but the operating COP of Haiwu waste heat recovery heat pump under this condition can reach more than 6.31, so that the unit energy consumption of 45°C hot water in all seasons can be reduced to less than 1/6 of traditional electric heating equipment.

(3) Heat recovery of Haiwu PHU all-weather energy-saving unit

PHU units were born under the pressure of the policy of "strict control of PUE and WUE", and the development concept has its own genes of saving, efficiency and environmental friendliness. Among them, the PHU model with heat recovery produced by Haiwu is a new "energy technology and information technology integration product" launched in 2022, which is to promote the development of the industry in the right direction with the goal of "building a green and low-carbon data center".

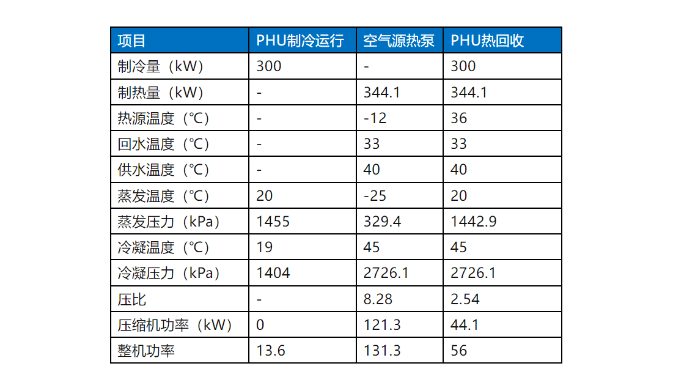

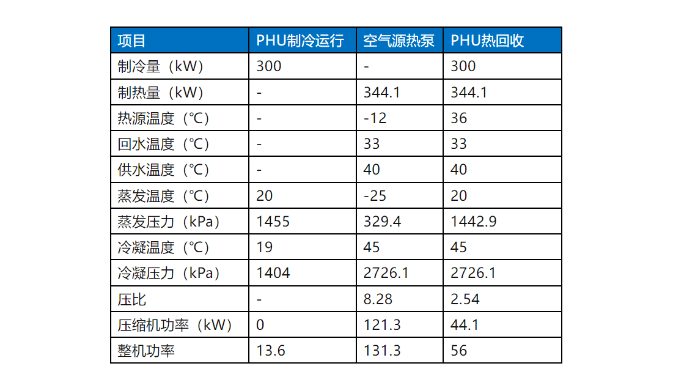

In the winter heating season, Haiwu PHU heat recovery unit can maintain a higher evaporation temperature, use a small pressure ratio compressor, produce heat energy with extreme efficiency, and the heating energy efficiency of the whole machine is significantly improved compared with the air source heat pump unit, which can be explored from the following comparison table:

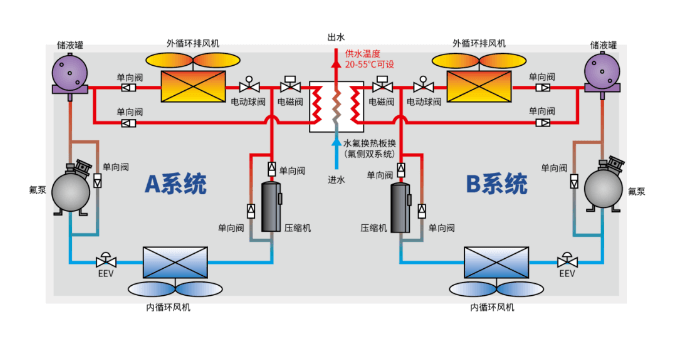

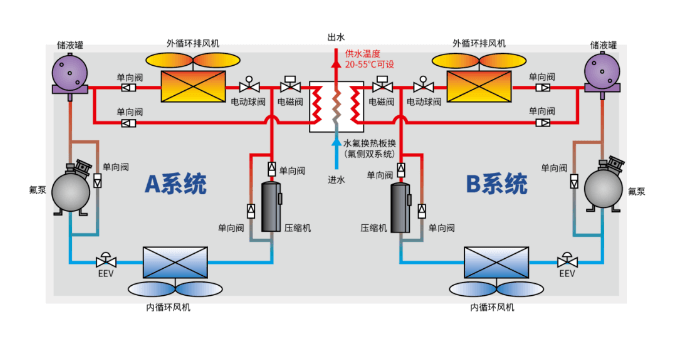

A heat recovery module (hydrofluorine heat exchange plate replacement) is connected in parallel on the compressor exhaust pipeline, and the heat flow control is controlled by the solenoid valve, the exhaust heat is recovered, and the heating hot water is provided. The heat supply of the whole machine is adjusted by solenoid valve and electric ball valve. The A/B system is graded to cut in/out of the heat recovery condition to avoid violent fluctuations in water temperature.

(4) Waste heat recovery in liquid-cooled data center schemes

The common characteristics of the three typical data center waste heat recovery technologies shown above are: the proportion of waste heat recovery and utilization in the total annual heat discharge is still very low, and the form of heat utilization is low-temperature hot water, and the use is also limited to washing, heating, breeding, printing and dyeing...... and other smaller fields. Due to the extremely limited transmission radius of low-temperature hot water, it is generally limited by the pipe network and pumping costs, and can only cover within 2-3 kilometers, and the location of the data center has special needs, and there is a high probability that there is a lack of suitable heat users in the surrounding area, resulting in the outreach of both supply and demand.

For example, in the cold plate liquid cooling scheme, the usual outlet water temperature of cold plate liquid cooling is up to 45°C, and the water source heat pump unit is directly added to the outlet pipe of the cold plate to produce hot water at a higher temperature, but the efficiency of this scheme for heat utilization is still not high. If the temperature of the chip is considered whether the liquid-cooled cold plate outlet temperature can be increased to 65°C, or even higher, usually the maximum temperature that can withstand the inside of the chip does not exceed 80°C, and if the outlet temperature of the cold plate can be raised to 65°C, which is more useful for direct use of waste heat for heat recovery. The same is true for immersion liquid cooling, which is more valuable for heat recovery if the temperature of the immersion liquid can be increased.

In short, the waste heat recovery of the data center is still in the exploration stage of the entire industry, and the current heating object is relatively single, and there is not much cooperation with related industries, the scale needs to be further expanded, the relevant technology needs to be further improved, and the heat energy utilization rate needs to be further improved. In this area, data center development is nowhere near what was expected. Where is the heat of the data center? It is worth considering and researching for all our data center practitioners, hoping to do more for the "dual carbon" strategy in terms of waste heat recovery.

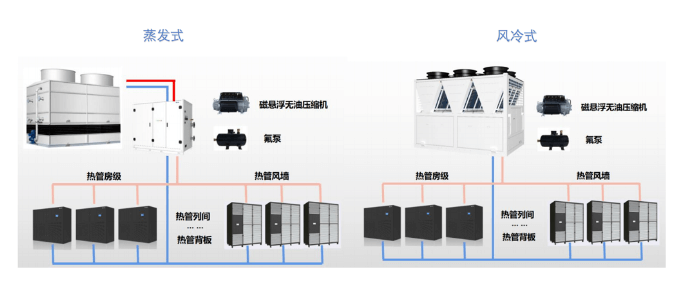

In addition to split fluorine pumps and integral fluorine pump PHUs, for large-scale data center scenarios and scenarios with extremely high requirements for PUE (e.g., PUE≤1.2), the magnetic levitation phase change multi-connection system can be used, which mainly applies magnetic levitation frequency conversion technology, evaporative condenser technology, frequency conversion fluorine pump technology, terminal multi-connection technology, etc. At present, the main cooling forms are magnetic levitation evaporative multiple system and magnetic levitation air-cooled multiple system.

In addition to the above three forms of fluorine pump system solutions, in order to adapt to the data center scenario with limited installation space of outdoor units, the fluorine pump multi-connection system was born, that is, the fluorine pump system that drags multiple indoor units from one outdoor unit, referred to as fluorine pump multi-connection. The fluorine pump multi-link also has three operating modes, such as Haiwu fluorine pump multi-link, its operation mode is as follows:

The 38°C hot air from the computer room flows through the evaporator of the heat pump unit added for waste heat recovery, and the temperature is reduced to 26~28°C, and the airflow principle is as follows:

Integrate data center cooling and office area heating to maximize the comprehensive utilization of energy. Its heat recovery principle is as follows:

Related Newsmore